|

| |

TM 5-4210-220-12

4-30 REAR AXLE - Continued

(21)

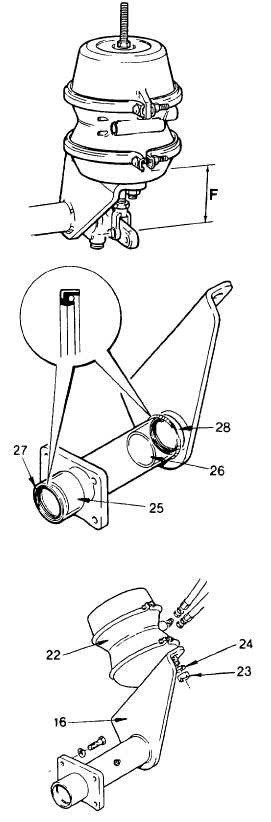

If brake air chamber is replaced, adjust

clevis position and push rod so that

distance F from chamber to center of clevis

pin holes equals 2 5/8 ± 1/16 in. (66.7 ± 1.6

mm).

CAUTION

Do not reuse a brake drum if the diameter

of the bore exceeds the manufacturers

recommended maximum or the total

indicated runout exceeds 0.020 in. (0.51

mm).

(22) Inspect brake drum for cracks, heat-checks,

glazing, grooving, runout and out-of-round.

If brake drum is cracked it must be

replaced. If drum is glazed, grooved, out-

of-round, etc, it may be turned in a lathe

and

reused

provided

the

maximum

diameter of the bore, stamped inside the

drum, is not exceeded.

INSTALLATION

(1)

If bushings (25 and 26) are replaced, use a

suitable

piloted

punch

to

drive

new

bushings in place. When correctly seated

bushing (25) should be in 1/4 in. (6.4 mm)

from end of tube and bushing (26) 21/32 in.

(16.7 mm) from other end of tube.

CAUTION

Improperly orientated seals may allow

grease to leak out of camshaft head and

contaminate brake drum and brake shoe

lining

(2)

Install seals (27 and 28) using a suitable

pilot. Be sure seal springs are facing in the

same direction, toward air chamber end of

bracket.

(3)

If

disassembled,

assemble

brake

air

chamber (22) and air chamber bracket (16)

using washers and nuts (23 and 24). Be

sure air hose ports in brake chamber face

away from bracket. Tighten nuts to 170 ft

lb (230 Nm).

4-573

|