|

| |

TM 5-4210-220-12

4-30. REAR AXLE - Continued

INSPECTION

(1)

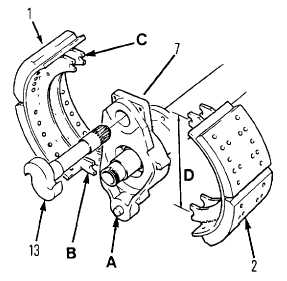

Inspect anchor pin (A) If pin is loose or

grooved more than 0.03 in. (0.8 mm) below

original surface, replace the spider.

(2)

Inspect brake shoes (1 and 2) and replace if

lining is contaminated, cracked or worn to

less than 1/4 in. (6.4 mm) thickness at any

point, or if rivets are closer to surface than

1/16 in. (1.6 mm) in any location.

(3)

Check brake shoes for bent or cracked

webs or table. Check also for broken weld

seams, loose rivets or elongated rivet

holes. Replace shoes if any of these

conditions are found.

(4)

Check shoe span by measuring the distance D

between centerlines of anchor pin and camshaft

roller recesses. If D is less than 12 5/16 in.

(312.7 mm) or more than 12 9/16 in. (319.1

mm) replace brake shoes.

(5)

Check anchor pin and camshaft roller recesses (B and C) for elongation or visible wear. Replace brake

shoes. If diameter of roller recesses (C) have been enlarged to 7/8 in. (22.43 mm) or greater use a piece

of 7/8 in. bar stock as a gage.

(6)

Inspect camshaft (13). Check for damaged or worn splines, corroded or worn bearing journals, and

brinelling, cracks or flat spots on camshaft head. Replace camshaft if worn or defective.

NOTE

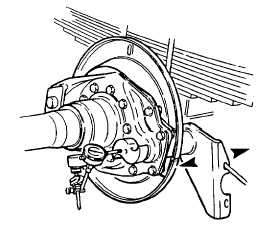

To carry out the following inspection procedure the camshaft, brake spider, air chamber

bracket, and slack adjuster including normally used shim washers must be assembled as

shown.

(7)

Check camshaft end play as detailed in

steps 8 thru 11 following

(8)

Mount a suitable dial indicator with the

plunger referencing the cam head at 90

deg. from cam face.

(9) Pull camshaft inward, ie., cam head toward

spider, to take up any end play and set dial

indicator to zero.

(10)

Push camshaft outward and note maximum

dial indication. The end play measured

should be 0.005 - 0.045 in. (0.13 - 1.14

mm).

4-571

|