|

| |

TM 5-4210-220-12

4-28. ENGINE - Continued

(4)

Pull

bearing

cap

into

position

be

alternately tightening the four attaching

bolts. Torque to 120 in. lb (14 Nm).

n.

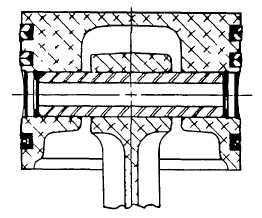

Cylinder Block Installation.

(1)

Place a new cylinder block to crankcase

gasket (4) on the crankcase (5). Place

the cylinder block (3) on the crankcase in

the same orientation as it was removed.

(2)

Assemble

the

six

bolts

(1)

and

lockwashers (2) torquing the two center

bolts to 8 ft lb (11 Nm), then the four end

bolts. Increase the bolt torque to 30 ft lb

(41 Nm), torquing the center two bolts and

then the four end bolts.

p.

Piston and Connecting Rod Assembly

(1)

Position connecting rod in piston and

press piston pin into place. This may be a

slip fit or light press fit.

(2)

Install snap rings into piston at the ends of

the piston pin.

NOTE

Compression

rings

must

be

installed

with

surface

marked

"TOP" facing top of the piston.

Some compression rings may

have dots indicating the top of the

ring.

(3)

Install compression and oil rails and expander rings on pistons. Seven rings are used in each piston, two

compression rings in each of the top two grooves, and two oil rails and an expander ring at the bottom.

(4)

Stagger ring gaps by 120 deg.

(5)

Press the connecting rod bearing inserts into the connecting rod and bearing cap. Make sure the

locating tangs on the inserts engage the locating notches in the rod and cap. Aline arrows on the cap

and rod as shown. Make sure each rod cap is installed on the rod from which it was removed.

(6)

Coat rod bearings with engine oil (item 17, Appendix E).

4-547

|