|

| |

TM 5-4210-220-12

4-26 DRIVE LINES, POWER TRAIN - Continued

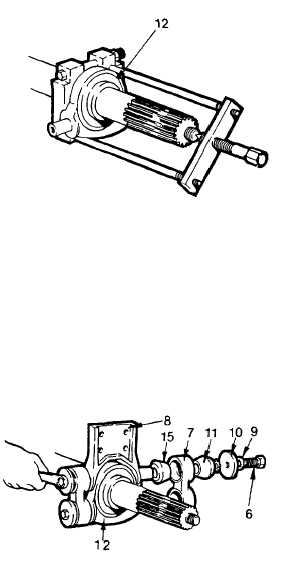

(10)

Using a mechanical puller and bearing separator,

as required, remove the center bearing and

housing assembly (12) from the shaft. Slide inner

cover off shaft.

(11)

Place bearing and assembly housing (12) in a

vise.

(12)

Wipe grease from bearing to access snap rings

retaining bearing.

(13)

Using two screwdrivers or suitable tools remove

the bearing retaining snap rings from the housing.

(14)

Set bearing and housing assembly up in a press if

required, and remove the bearing from the

housing (12). Discard the bearing.

INSPECTION

WARNING

Dry cleaning solvent P-D-680 (safety or

Stoddard's

solvent)

is

potentially

dangerous.

Avoid

repeated

and

prolonged breathing of vapors and skin

contact with the liquid. Do not use near

open flame, arcing equipment or other

ignition sources. Always wear eye

protection and protective clothing. The

flash point of P-D-680 is 100 to 138 deg.

F (30 to 59 deg. C).

(1)

Using dry cleaning solvent (item 10, Appendix E),

wash all components of center bearing except for

the rubber bushings (14 and 15).

WARNING

Death or serious injury could occur if

compressed air is directed against the

skin. Do not use compressed air for

cleaning or drying unless the pressure

is/has been reduced to 30 psi (2.11

kg/cm2) or less. When working with

compressed air always use chip guards,

eye

protection

and

other

personnel

protective equipment.

(2)

After

washing,

dry

the

components

using

compressed air.

4-515

|