|

| |

TM 5-4210-220-12

4-26. DRIVE LINES, POWER TRAIN - Continued

WARNING

Death or serious injury could occur if

compressed air is directed against the

skin. Do not use compressed air for

cleaning

or

drying

unless

the

pressure is/has been reduced to 30

psi (2.11 kg/cm2) or less. When

working with compressed air always

use chip guards, eye protection and

other personal protective equipment.

(2)

After washing, dry the components using

compressed air.

(3)

Inspect splines and threads for damage

such as wear, pitting, flaking, rolling,

peening and fatigue cracks.

(4)

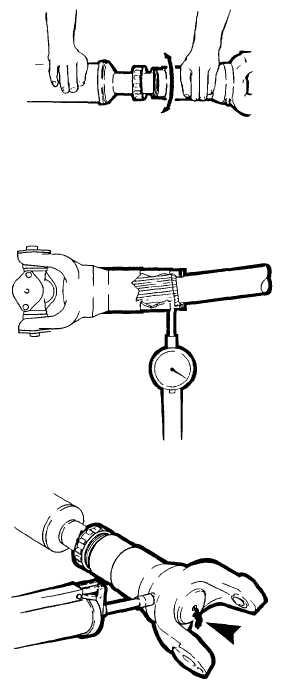

Install slip yoke assembly on to splined

stub shaft.

(5)

Using an opposing to and fro twisting

motion visually check the movement

between the two shafts. If play seems to

be excessive, use a dial gauge to

measure the movement. The movement

must not exceed 0.007 in. (0.18 mm).

(6)

Inspect dust cap. If it is severely bent, or

threads are stripped, replace it.

(7)

Qualify cross hole alinement, see para. 4-

26.1.

(8)

Evidence of damage of any kind is cause

for rejection. Replace component or

assembly as required.

ASSEMBLY .

(1)

Install splined stub shaft into slip yoke

assembly.

(2)

Ensure that both yokes are in matched

position.

(3)

Using pliers, Install and tighten dust cap.

(4)

Once assembled, lubricate the slip joint

assembly until grease (item 16, Appendix

E) is expelled from pressure relief hole in

welch plug. Cover pressure relief hole

and continue lubricating until grease

appears at slip yoke dust cap (1).

4-501

|