|

| |

TM 5-4210-220-12

4-26. DRIVE LINES, POWER TRAIN - Continued

4-26.2 Slip Joint Yoke.

This task covers

a.

Disassembly

b.

Inspection

c.

Assembly

TOOLS

Shop Equipment, General

Purpose Equipment,

FSN 4940-287-4894

2, Appendix G Alinement Bar

EQUIPMENT CONDITION

Appropriate Drive Shaft Removed (see para. 4-26.3)

MATERIALS/PARTS

10, Appendix E Dry Cleaning Solvent

16, Appendix E Grease EP1

20, Appendix E Penetrating Oil

6-3-2651 KX Slip Yoke

DISASSEMBLY

NOTE

The two slip joints used on this

truck are the same. The steps

described below refer to either

slip joint. If components are

excessively

corroded,

apply

penetrating oil (item 20, Appendix

E) to ease disassembly.

(1)

Mark slip joint before removal, this will

ensure alinement of components during

installation.

(2)

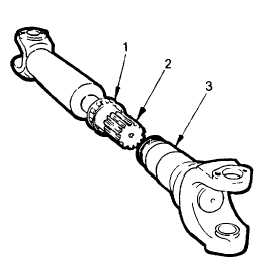

Use pliers to remove dust cap (1).

(3)

Separate the two shafts (2 and 3).

.

INSPECTION.

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard's solvent) is potentially dangerous. Avoid

repeated and prolonged breathing of vapors and skin contact with the liquid. Do not use near

open flame, arcing equipment or other ignition sources. Always wear eye protection and

protective clothing. The flash point of P-D-680 is 100 to 138 deg. F (30 to 59 deg. C).

(1)

Using dry cleaning solvent (item 10, Appendix E), wash splined stub shaft (2), slip yoke assembly (3) and

dust cap (1).

4-500

|