|

| |

TM 5-4210-220-12

4-24. ELECTRICAL SYSTEM

4-24.1 Alternator

This task covers

a.

Test

b.

Replacement

c.

Repair

TOOLS

MATERIALS/PARTS

Shop Equipment, Automotive

1105465 Alternator

Maintenance and Repair,

NSN 4910-00-754-0650

EQUIPMENT CONDITION

Main Engine Shutdown (see para. 2-10)

APU Shutdown (see para. 2-12)

Battery Switch OFF

110 Volt Inverter OFF

LHS and RHS Engine Cover Removed

(see para. 4-12.11)

TEST

NOTE

If the batteries are undercharged carry out tests 1 thru 11. If the batteries are overcharged, or

showing low electrolyte level, carry out test 12 thru 14.

(1)

Be sure undercharging is not a result of accessories being left on. With all accessories off and battery

switch set to BOTH and batteries charged, connect a voltmeter between the terminals of the current shunt.

The reading should be zero even in the millivolt range. If there is a reading, check for a broken accessory

switch or an accessory circuit connected directly to the battery bus bar. The current shunt is mounted on

the left hand engine lifting bracket.

(2)

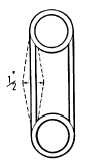

Be sure alternator drive belts are tight. There should be a maximum 1/2 in. (12 mm) play in drive belt at

the mid-position between the pulleys.

(3)

Be sure all battery, starter motor, alternator, and ground connections are tight and clean. Be sure battery

posts are not coated with corrosion products.

(4)

Switch ignition on and note dash-mounted voltmeter reading. A zero reading indicates wire 22 or 21 or the

wires between the batteries and battery switch are broken. It may also indicate a fault with the battery

switch or the ignition switch. Check all wire and switches and replace failed components.

Change 4 4-412

|