|

| |

TM 5-4210-220-12

4-22. AIR SYSTEM - Continued

(5)

When all air tanks are at pressure, make several brake applications and check for prompt application and

release of the rear brakes

(6)

With the service brakes released, brush the exhaust port and area around the retaining ring with soap

solution A 1 in. (2.5 cm) bubble in 3 seconds leakage is permitted

(7)

With the service brakes applied, brush the exhaust port with soap solution. A 1 in. (2.5 cm) bubble In 3

seconds leakage is permitted.

(8)

With the service brakes applied, brush the outside of the valve, where the cover joins the body, and each

hose connector with soap solution. No leakage is permitted.

(9)

If the body or a connector leaks, tighten or remake connections as required. If the exhaust port leaks,

repair the valve as detailed in REPAIR following.

REPAIR

NOTE

The relay valve can only be

repaired if it is removed from the

truck. See REMOVAL preceding.

Prior to disassembly, mark the

location of the mounting bracket to

the cover and the cover to the

body.

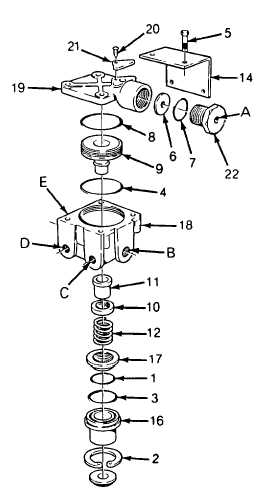

(1)

Remove the four capscrews (5) and

lockwashers securing the cover (19) to the

body

(2)

Remove the cover (19), ring (8), and

mounting bracket (14)

(3)

Remove the piston (9) and O-ring (4) from

the body (18)

(4)

While depressing the exhaust cover (16),

remove the retaining ring (2, 8) and slowly

relax the spring (12) beneath the exhaust

cover

(5)

Remove the exhaust cover assembly.

Remove O-ring retainer (17) from exhaust

cover and remove O-rings (1 and 3)

(6)

Remove the inlet/exhaust valve return

spring (12) from the body

(7)

Remove the inlet/exhaust valve (11) from

the body

(8)

Remove the valve retainer (10) from the

inlet/exhaust valve

4-349

|