|

| |

TM 5-4210-220-12

4-18. PUMP, PIPING, AND VALVES-Continued

4-18.11 Air Actuated Ball Valves.

This task covers

a.

Removal

b.

Installation

c.

Adjustment

TOOLS

Shop Equipment, Automotive

Maintenance and Repair,

NSN 4910-00-754-0705

EQUIPMENT CONDITION

All Piping Drained

Foam Tank Drained (see para. 2-13)

Main Engine Shutdown (see para. 2-10)

APU Shutdown (see para. 2-12)

Batteries Disconnected (see para. 4-24)

Pump Body Heat Shield Removed (see para. 4-11.2)

MATERIALS/PARTS

11, Appendix E Electrical Tape

22, Appendix E Pipe Sealant

NOTE

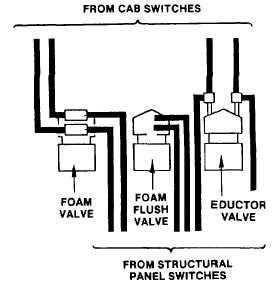

The following is a general remove/install

procedure. To remove/install a specific air

actuating

ball

valve

use

the

following

illustration as a guide. It may be necessary to

remove the actuator prior to ball valve removal.

REMOVAL

(1)

Disable the switching system by setting the cab MODE

switch to mid-position. Tag this switch identifying

'Repairs in Progress'.

(2)

Bleed the air from the actuator by setting the cab

WATER EDUCTOR and FOAM VALVE switch to mid-

position.

(3)

Bleed the structural panel air lines by setting the FOAM

VALVE, WATER EDUCTOR and FLUSH switches to mid-position.

(4)

Tag and remove the air lines from the air actuated ball valve being removed. Tagging will ensure proper

assembly.

NOTE

If only the ball valve is being removed it is acceptable to leave air lines connected and to

suspend the actuator from the frame using mechanics wire.

4-244

|