|

| |

TM 5-4210-220-12

4-18 PUMP, PIPING, AND VALVES - Continued

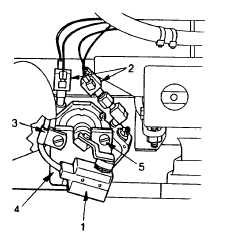

(7)

Apply pipe sealant (item 22, Appendix E) to threads and install (3) into shuttle valve ports in

orientation shown.

(8)

Install and tighten air lines (1) to their proper location on shuttle valve (2) as shown.

(9)

Test valve and connections by operating the valve a few times from both the cab and the structural

control panel. (For cab operation, mode switch must be set to CFR, for structural panel operation,

mode switch must be set to STRUCT). Tighten and/or remake connections as required.

(10)

Be sure cab lamp illuminates when valve is open (Batteries connected and Ignition ON).

Adjust microswitch as required.

c.

Actuator Repair

(1)

Remove microswitch (1) as detailed in Microswitch Repair

preceding.

(2)

Remove both shuttle valves (2) as detailed in Shuttle

Valve Repair preceding.

(3)

Remove the microswitch wiring support clamp (3) and

microswitch bracket (4) by removing screws (5).

(4)

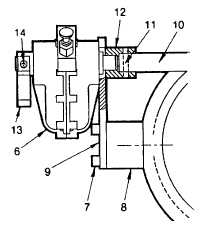

Remove the remaining shuttle valve fittings from the

actuator (6).

(5)

Remove the microswitch cam (13) from the actuator shaft.

(6)

While supporting the actuator (6), remove the four machine screws (7).

(7)

Separate the actuator (6) from the check valve extended hinge pin (10).

(8)

Inspect all fittings for stripped threads, or cracks that may cause an air leak.

(9)

Drill through and tap (#10-32) the actuator shaft in order to

attach cam (13) to shaft.

(10)

Lift new actuator (6) into position.

(11)

Aline actuator coupling (12) with roll pin (11).

(12)

Aline actuator mounting holes to valve and install machine

screws (7).

(13)

Apply pipe sealant (item 22, Appendix E) to threads and install

shuttle valve fittings in the orientation shown.

4-231

|