|

| |

TM 5-4210-220-12

4-18. PUMP, PIPING, AND VALVES - Continued

4-18.1 Fire Pump - Continued

INSTALLATION

WARNING

Serious injury could occur if heavy equipment is moved/lifted without sufficient personnel to do the

job. Use proper physical lifting procedures or use a suitable lifting device or dolly. Wear safety

shoes, gloves and other suitable protective clothing.

(1) Be sure the suction tube, the volute body

and their mating surfaces are clean prior to

re-gasketing.

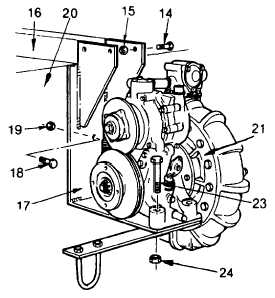

(2) Set the pump (21) on the pump mounting

bracket (17) and align the mounting holes.

(3) Install the two innermost capscrews (23) and

new locknuts (24) and tighten to 270 ft lb

(266 Nm).

(4) Lift the pump and bracket assembly off the

workbench and set it on the saddle of a

dolly type hydraulic jack.

(5) Apply gasket eliminator (Item 14, Appendix

E) to the volute body and suction tube

flanges.

(6) Carefully raise the dolly type hydraulic jack

until the mounting holes in the pump

mounting bracket (17) align with the holes

in the mounting channel (16). Align the

suction tube and volute body flanges with

their

respective

piping

and

install

capscrews and locknuts fingertight.

(7) Install the four capscrews (14) and new

locknuts (15) used to fasten the pump

mounting bracket (17) to the mounting

channel (16). Tighten the locknuts to 160

ft lb (217 Nm).

(8) Align the mounting holes in the pump mounting bracket (17) with the holes in the frame side member (20).

(9) Install the four capscrews (18) and new locknuts (19) used to fasten the pump bracket (17) to the frame

side member (20). Tighten the locknuts to 160 ft lb (217 Nm).

(10) Remove the block of wood used to support the mounting channel during pump removal.

4-218

|