|

| |

TM 5-4120-220-12

4-15. AUXILIARY POWER UNIT - Continued

INSPECTION

(1)

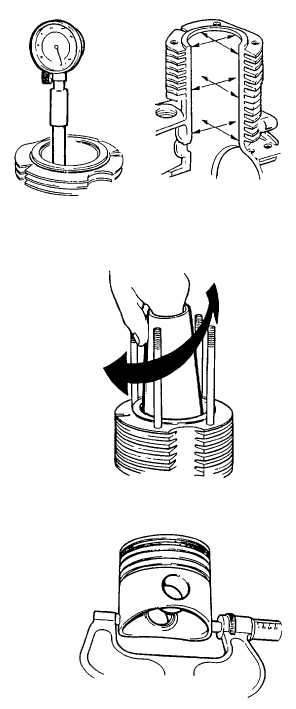

Check cylinder wall out of round and taper with dial

gage at two diameters a and b perpendicular to each

other. Check at three different heights as illustrated.

(2)

If cylinder diameter is more than 0.004 in. (0.10 mm)

nominal (see below), or is out of round by more than

0.002 in. (0.05 mm), or is tapered more than 0.004

in. (0.10 mm), cylinder block must either be replaced

or rebored to accept an oversize piston.

Nominal 3.0732 - 3.0740 in. (78.00 - 78.02 mm)

First oversize 3.0929 - 3.0937 in. (78.50 - 78-52 mm)

Second oversize 3.1126 - 3.1134 in. (79.00 - 79.02

mm)

Oversize piston and rings must also be installed.

(3)

If cylinder diameter is less than 0.004 in. (0.10 mm)

nominal (see step 2 preceding), or is out of round by

less than 0.002 in. (0.05 mm), or is tapered less than

0.004 in. (0.10 mm), piston rings should be replaced

on original piston, if piston is not damaged. (See step

5 following).

(4)

Restore roughness to cylinder by honing with emery

cloth (item 12, Appendix E) soaked in diesel fuel, or

with honing tool. Work in helical movement to obtain

a cross hatch surface pattern.

(5)

Inspect piston, removing any scale, or carbon

deposits on head. Measure piston skirt diameter

perpendicular to wrist pin bore as illustrated.

(6)

Maximum skirt wear must not exceed 0.002 in. (0.05

mm)

Nominal 3.0693 - 3.0697 in. (77.90 - 77.91 mm)

1st oversize 3.0890 - 3.0894 in. (78.40 - 78.41 mm)

2nd oversize 3.1087 - 3.1091 in. (78.90 - 78.91 mm)

Replace piston as required.

(7)

Measure

wrist

pin

bore

for

out-of-roundness.

Replace piston and wrist pin if out-of-roundness

exceeds 0.004 in. (0.10 mm).

(8)

Inspect wrist pin for scoring or seizure marks.

Replace piston and piston pin if any found.

(9)

Measure wrist pin diameter and wrist pin bushing in

piston rod. Replace both if clearance exceeds

0.0025 in. (0.07 mm).

4-171

|