|

| |

TM 5-4210-220-12

4-15.

AUXILIARY POWER UNIT- Continued

4-15.6

Engine Injector Pump - Continued

TEST

NOTE

May be tested with APU in truck.

(1)

Remove pressure line between injection

pump and injector.

(2)

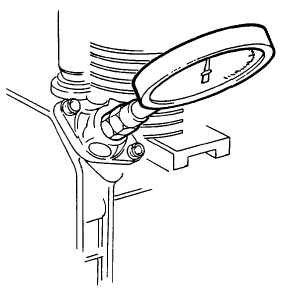

Connect a 0 - 10,000 psi (0 - 70,000 kPa)

pressure gage to delivery union.

(3) Set APU keyswitch to ON Check fuel

pump starts.

(4)

Set control rack to mid-position, APU

throttle to mid position.

(5)

Rotate

engine

through

several

revolutions, using starter motor (keyswitch

set to START), This will purge all air from

the fuel system.

(6)

While watching pressure gage, rotate engine through a complete injection cycle.

(7)

Note maximum pressure on gage.

(8)

Repeat test with control rack in fully open position, APU throttle in maximum position.

(9)

If first test pressure is less than 4000 psi (28,000 kPa) or second test pressure is less than 5500 psi (38,000

kPa) replace injector pump assembly or replace plunger and barrel (see REPAIR following).

(10)

Repeat the test and note the pressure drop that immediately follows the peak pressure reading. Pressure

drop should be between 400 - 700 psi (2800 - 4800 kPa).

(11)

If test pressure is not reached, replace pump assembly (see REMOVAL following) or replace delivery valve

(see REPAIR following).

REMOVAL

(1)

Remove banjo bolt (1), both washers (2), banjo bolt (3), and both washers (4).

(2)

Remove high pressure injector feed line (5) and clamp retaining bolt (6).

(3)

Remove both machine screws (7) and washers (8).

(4)

Carefully withdraw injector pump (9) from block. Take care to ensure gaskets (10), spacer (11), and tappet

(12) are removed from the block.

4-158

|