|

|||

|

|

|||

|

Page Title:

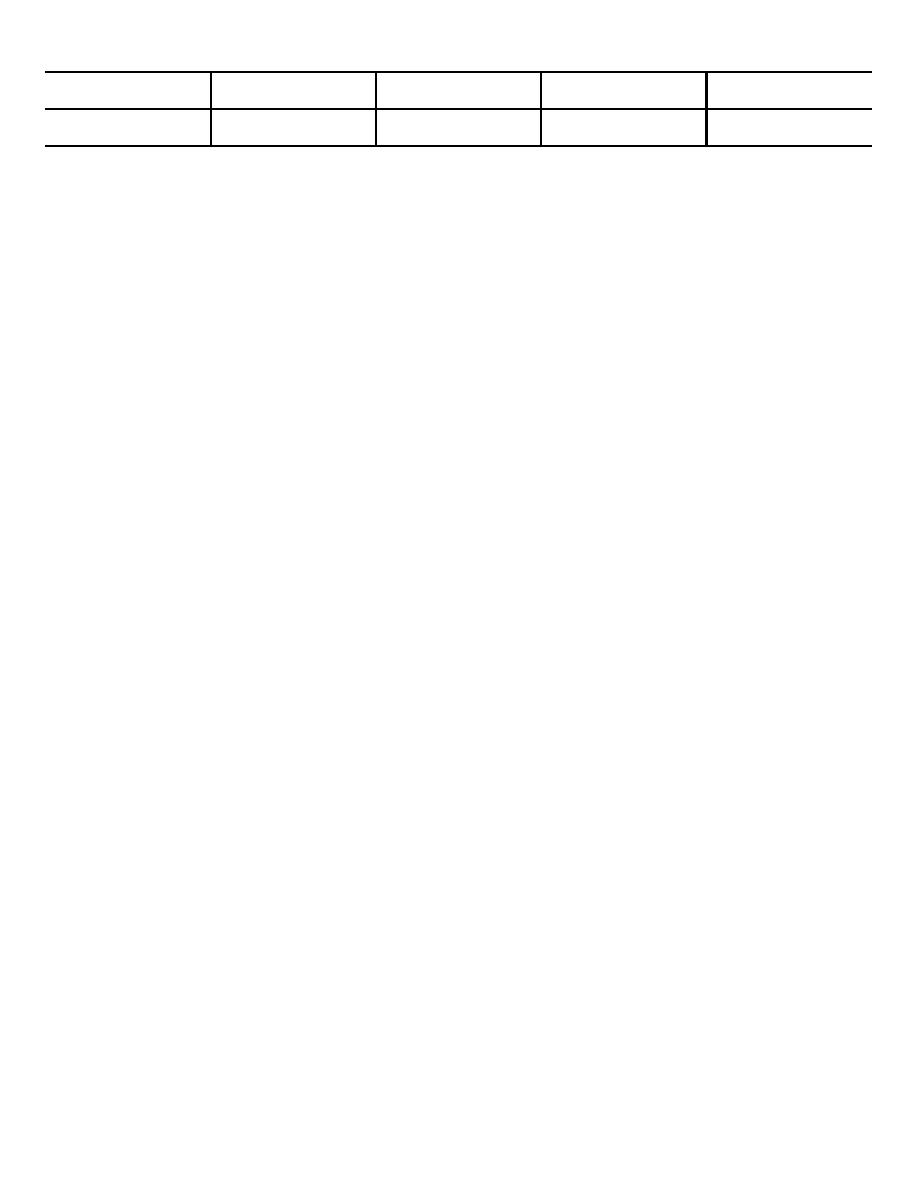

Figure 71.29. Fuel regulator valve test chart. |

|

||

| ||||||||||

|

|

Fuel Flow

Pressure

Fuel Flow

Pressure

(cc/min.)

(psig)

(cc/min.)

(psig)

22

14.5

Minimum

28

20.2

19.5

10.15

Maximum

Figure 71.29. Fuel regulator valve test chart.

c.

Install Fuel Regulator Valve and nozzle

tee, install the adapter tee with nozzle

assembly. Connect a fuel supply capable

assembly.

of supplying a steady flow of fuel under

(1) Position the fuel regulator valve (19, fig.

constant pressure of 3 to 5 psig to the

71.28) on the control head base (20) and

regulator valve inlet port. Connect the

fasten with two screws (23). Connect

fuel tube (13, fig. 71.35) to the tee and

wires as shown in the wiring diagram (fig.

allow the fuel to flow into a measuring

71.12).

graduate (approximately 50-100 ml).

(2) Install the nozzle assembly (19, fig. 71.35)

(2)

Connect the nominal voltage power

in the adapter tee (17, fig. 71.28) and

supply to both sides of the regulator valve

insert the pipe plug (18, fig. 71.35).

and make provision to energize one or

(3) Install the elbow (18, fig. 71.28) and the

both sides of the valve.

tee on the outlet port of the fuel regulator

(3)

Operate the test setup to energize the

valve.

shut-off valve (nameplate end) of the

(4) Attach nut (16, fig. 71.35), sleeve (17) and

regulator valve and to supply fuel to the

fuel tube (15) to the adapter tee. Install

system. The fuel flow should be within

the control head assembly.

the limits shown in the fuel regulator valve

test chart below for the model heater

194. Liquid Heater Disassembly

tested. Break the circuit, and the fuel flow

(fig. 71.30).

should stop immediately.

a. Removal. Refer to figure 71.31 for removal.

(4)

Connect both sides of the regulator valve

b. Control Head Assembly Removal.

to the power supply and note the fuel flow

(1) Remove two screws (12) from the control

and pressure. The fuel flow and pressure

head cover (18) and lift cover.

should be within the limits shown in figure

(2) Disconnect ignition coil high-tension wire

71.29. Break the circuit, and the fuel flow

from

the

spark

plug

assembly.

should stop immediately.

Disconnect both primary wires leading to

(5)

If outlet pressures do not conform to

the ignition coil.

specification or fuel flow does not stop

(3) Loosen the fuel tube nuts (16) and

during test, the fuel regulator valve is

remove the fuel tube (15) and sleeves

faulty and should be replaced.

17).

(6)

If outlet pressures do conform but the fuel

(4) Disconnect at their terminal points the

flow is lower than specified during tests,

three wires extending through the

the nozzle assembly is clogged. Clean

grommet (48) in the heater casing.

the passages of the nozzle assembly with

Unscrew the flame switch mounting nut.

air. Do not attempt to clean the regulator

with any type of instrument.

(5) Remove the two wires from the limit

switch (2) and disconnect the wire

(7)

If outlet pressures do conform, but the

fuel flow is higher than specified during

tests, replace a faulty nozzle assembly.

AGO 5667A

29

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |