|

| |

Pressure regulator valve and test fixture

valve(s) should be left in the closed position

when not in use. Leaving valves open could

result in damage to unit diaphragms.

2-4. TIME CYCLES.

a.

Maintenance personnel will purge and charge tank

fire control items every 180 days and artillery fire control

items every 90 days or when condensation is evident in the

instrument.

b.

NOTE

The 180-day cycle does not apply to rangefinders

which are purged and charged once a year. How-

ever, a visual inspection is required every 90 days

for evidence of moisture. The electrical compo-

nents of M21 Ballistic Computer System to in-

clude the Ammo Select Unit, Cant Angle Sensor,

Computer Unit, Output Unit and Rate Tachome-

ter and the Laser Rangefinder, AN/VVG–2, Elec-

tronics Unit require purging every 180 days,

when unit is opened for maintenance, or when ev-

idence of moisture is present.

Maintenance personnel will purge and charge fire

control materiel being repaired whenever the repair func-

tion affects internal sealing.

c.

For maintenance of material in storage refer to appli-

cable equipment manuals.

d. NSN’s 4820-01-384-9005 and 4730-00-277-9615

are mandatory for purging artillery fire control.

2-5. PURGING

DURES.

TM 750-116

AND CHARGING PROCE-

a. Purge and Charge: Inlet Port Entry, Relief

Valve Exit. This procedure is used when instrument is

designed to hold a charge.

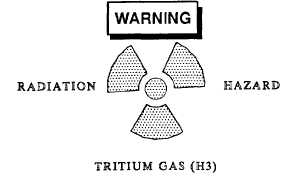

HANDLE WITH CARE. IN THE EVENT

THE RADIOLUMINOUS SOURCE IS

BROKEN, CRACKED, OR SUDDENLY

LOSES ILLUMINATION, DO NOT AT-

TEMPT TO REPAIR. IMMEDIATELY

WRAP DEVICE IN PLASTIC AND

NOTIFY THE LOCAL RADIATION PRO-

TECTION OFFICER (RPO).

(1) Remove inlet port cap of instrument to be purged

and charged.

(2) Inspect inlet port for cleanliness and presence of

valve core. Remove any dirt or foreign matter.

Ensure regulator valve is closed (counter-

clockwise - CCW) or damage may occur to

regulator.

To avoid damage to instruments being

purged and charged, do not exceed maxi-

mum pressure. Unless otherwise noted for

specific instrument, maximum pressure is 10

psi.

(3) Connect hose assembly to inlet pert on instrument.

(4) Open main valve on nitrogen tank (CCW).

(5) Open regulator valve (clockwise - CW) until spe-

cified purge pressure is indicated on low pressure gage.

(6) Watch low pressure gage and listen for purge relief

valve to open.

(a) Relief valve should open between specified

pressures.

(b) If relief valve does not open before pressure

reaches maximum range, immediately turn off regulator

valve (CCW). Replace pressure relief valve on instrument.

Repeat procedure.

Change 1 2-3

|