|

| |

TM 5-4210-233-14&P-1

5-22.

BLOWER REPAIR - Continued

NOTE

Repeat steps (30) through (33) for

front and rear end plates.

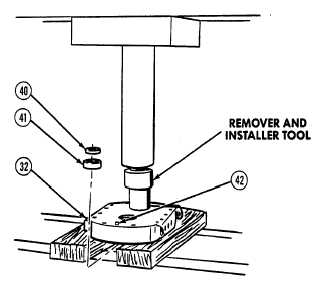

(30)

Position rear end plate (32) on

wood blocks.

(31)

Place long end of remover and

installer tool through seal ring

collar (40) into ball bearing (41).

(32)

Press out ball bearing (41) and

seal ring collar (40).

(33)

Inspect dowel pins (42) for

breakage or damage. Replace if

broken or damaged.

b.

Cleaning/Inspection.

WARNING

Dry cleaning solvent P-D-680 is potentially dangerous.

Avoid repeated and prolonged breathing of vapors and skin

contact with the liquid. Do not use near open flame, arcing

equipment or other ignition sources. Always wear eye

protection and protective clothing. The flash point of P-D-

680 is 100 to 138 deg. F (38 to 59 deg. C).

Death or serious injury could occur if compressed air is

directed against the skin. Do not use compressed air for

cleaning or drying unless the pressure is/has been reduced

to 30 psi (2.11 kg/cm2) or less. When working with

compressed air, always use chip guards, eye protection, and

other personal protective equipment.

CAUTION

Do not use compressed air on bearings. Allow bearings to air dry. Compressed air

may cause damage to bearings.

(1) Clean metal parts in dry cleaning solvent (Item 3, Appendix E). Dry parts other than bearings with

compressed air.

(2) Examine the bearings for any indications of corrosion or pitting. Lubricate each ball bearing with light

engine oil (Item 10, Appendix E). Then, while holding the bearing inner race from turning, revolve the

outer race slowly by hand and check for rough spots. The double-row ball bearings are pre-loaded and

have no end play. A new bearing will seem to have considerable resistance to motion when revolved

by hand.

5-129

|