|

| |

TM 5-4210-233-14&P-1

5-66. APU GENERATOR-Continued

(11)

Check the field winding resistance from F2 in the control box to the F + connection on the

generator (F + is connected to the positive brushes). Resistance should be 1.46 ohms on standard

ac models. Other models will have the following resistances:

2.06 ohms for 24-volt cranking

3.80 ohms for 32-volt cranking

0.80 ohms for transistor flicker

5.14 ohms for 24-volt battery charger

8.8 ohms for 32-volt battery charger

If the windings are warm from running, the resistance will be slightly higher. If the resistance is

high, check for an open circuit in one of the parallel windings, step 12, otherwise go to step 13.

(12) Separate the parallel field windings (at F +) and

check each for open circuit.

(13)

Check for open circuit in the series winding

with ohmmeter. Touch probes to lead S1 and

connection F +. If there is an open circuit,

isolate each coil and check ft.

(14)

Test for short circuit between the starter

windings and the shunt windings. Before

doing this, separate all windings at F +.

(15)

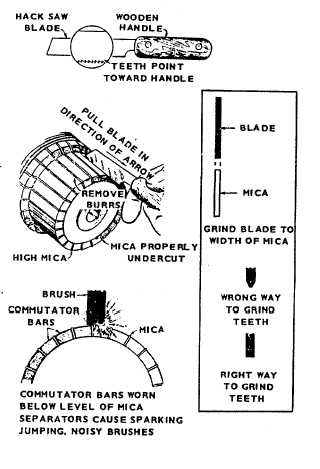

Commutator Repair: The commutator bars

wear down with use, so eventually the mica

between them extends over the tops of the

bars and causes sparking and noisy brushes.

When the mica on any part of the commutator

is touching the brushes, it must be undercut.

A suitable undercutting tool can be made from

a hacksaw blade. Be careful not to injur the

bars. After undercutting, remove any burrs

formed on the bars. Cut the mica to about

1/32" under the bars.

(16)

If the commutator is grooved, out-of-round, or

otherwise damaged, refinish it. Turn it in a

lathe and then undercut the mica as described

above.

Shield

the

ball

bearing

during

refinishing. Do not use turning centers on

shaft because they probably have been

damaged and are no longer true centers.

Commutator and slip ring run out should be

less than .002 in.

(17)

Brush Rig Alignment: The brush rig must

be aligned in the neutral position. If it isn't

sparking will occur. Normally the neutral

position is identified by a yellow mark

extending from the brush rig to the endbell. If

the mark is lost, or a new brush rig installed,

follow these instructions to find the neutral

position.

5-368

|