|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

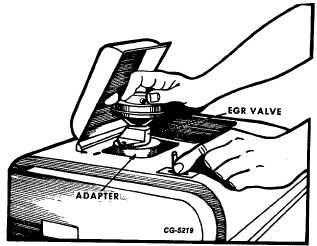

deposits from pintle and seat, if necessary.

To clean deposits from pintle and seat of EGR valve, use

a sand blast type spark plug cleaner and the following

procedure:

(1)

Prepare spark plug cleaner by installing rubber

adapter with 22 mm (7/8") hole over cleaning

(blast) port. Do not install metal adapter clamp

(Fig. 50).

(2)

Insert pintle of EGR valve through hole in rubber

plug cleaner adapter.

(3)

Holding EGR valve tightly down adapter, apply

sand blast to clean pintle.

CAUTION

Safety

goggles

should

be

worn

while

performing cleaning operation.

Fig. 50 Cleaning EGRH Valve

(4)

After cleaning exposed pintle, hold EGR valve in

both hands and press in diaphragm to retract

valve pintle into valve housing. Use a 25 mm

(1") long bolt (3/4" long for dual diaphragm

valves) to hold pintle in retracted position. Apply

masking tape to cover outlet port of valve.

(5)

With pintle opening of valve aligned with hole in

cleaning adapter, hold EGR valve down tightly

against adapter and apply sand blast to clean

interior of valve housing and valve seat.

d.

After cleaning, blow all excess sand from interior of

valve housing and remove bolt.

e.

Recheck valve for proper operation and seating.

f.

Replace with new valve, if necessary.

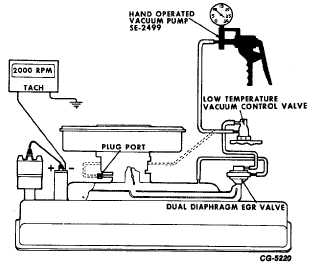

15. Check EGR System with Functional Test and Clean or

Replace, If necessary. (V-345 and V-392 Engines

Only)

Perform EGR System Functional Test as follows:

a.

Operate engine until it reaches normal operating

temperature.

b.

Shut off engine. Connect tachometer. Connect

vacuum pump with vacuum gauge to EGR system

vacuum hose at carburetor.

c.

Plug fitting at carburetor.

d.

With tachometer installed, operate all engines at

2000 RPM.

e.

Apply specified vacuum (see Emission Control

System Tune-Up Specifications).

Fig. 51 Complete EGR System Test

f.

See

Emission

Control

System

Tune-Up

Specifications for engine speed drop when vacuum is

applied. This procedure checks not only the EGR

valve but the intake manifold and related passages

as well.

CGES-215 Page 28

PRINTED IN UNITED STATES OF AMERICA

|