|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

b.

With engine off, inlet tube damper should be in full

down position to close heat tube inlet pipe from

exhaust manifold stove. Damper position can be

determined by looking in end of inlet tube. If damper

assembly is not in the correct position, vacuum

chamber should be removed and damper movement

loosened. Replace vacuum chamber (located on top

of inlet tube) and recheck damper position.

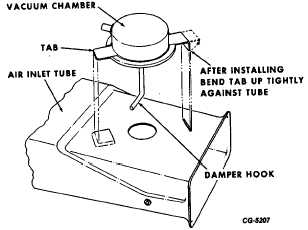

Fig. 42 Vacuum Chamber Details

To replace vacuum chamber (Fig. 42) (cannot be

replaced on air cleaners used on 4-196 engines)

bend tab nearest inlet tube entrance down from

inside tube. Disconnect vacuum hose and lift

vacuum chamber, sliding the rear tab out of its slot

disengaging damper hook from damper. Attach new

chamber by engaging hook in damper, sliding rear

tab into its slot and fitting front tab into place. A

spring preload should be felt when vacuum chamber

is pressed firmly against top of inlet tube. If no

preload is felt, check the installation or be sure parts

are not faulty. Press front vacuum chamber tab

firmly against tube inside surface. Connect vacuum

hose.

c.

Start engine and note that damper has rotated up to

close off cold air inlet. Observe damper position by

looking in the inlet tube. If damper did not

immediately close cold air inlet, proceed as follows:

(1) Shut off engine and disconnect the two hoses from

sensor.

(2) Connect the two hose ends together using suitable

tubing.

(3) Restart engine and again check damper location. If

damper fully closes cold air inlet, temperature sensor is

defective and must be replaced (located inside air cleaner

body).

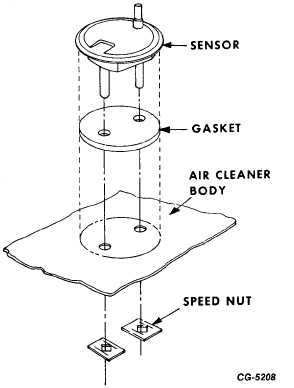

Fig. 43 Sensor Installation

To replace temperature sensor, disconnect two

vacuum hoses attached to sensor inlet and outlet

tubes on underside of air cleaner body. Remove

clamps or speed nuts from tubes and lift sensor from

body. Position new sensor and gasket inside air

cleaner body. Firmly press two new speed nuts or

clamps on tubes to hold sensor in place. Attach

vacuum hoses to sensor tubes. If damper does not

close cold air inlet, sensor is okay, but damper has

bind or vacuum chamber is defective. Remove

vacuum chamber and check damper for free

movement. If damper moves freely, replace vacuum

chamber.

d.

After cold start, operate engine for 10 minutes at

medium RPM. When engine is at normal operating

temperature, slow

CGES-215 Page 25

PRINTED IN UNITED STATES OF AMERICA

|