|

| |

TM 5-4210-230-14&P-1

VEHICLE MAINTENANCE

2.

Remove retaining nut and gasket from cover.

3.

Remove filter case by tapping lightly on case.

4.

Remove the used filter element.

5.

Wash filter case and internal parts in cleaning solution and air dry.

6.

Check the cover gasket. Replace if necessary.

7.

Install spring, washer, gasket, support cup and new filter element over filter case stud and into case.

8.

Install filter case and assembled components to filter cover. Hold in position and install retaining nut and gasket. Tighten

the nut securely.

9.

Install drain plug and tighten securely.

10.

Raise the air pressure and check for leaks.

OIL FILTER

If your vehicle is equipped with a transmission oil filter, it has a replaceable element. See Lubrication Section for servicing.

U-BOLTS

1.

After the chassis has been operating under load for 1600 km (1000 miles), or six months whichever comes first, the U-bolt

nuts must be retorqued.

2.

The U-Bolt nuts thereafter should then be retorqued every 58,000 km (36,000 miles).

3.

The U-Bolt (joint) should be cleaned and free of corrosion as in a new or as-new condition .

U-BOLT NUTS

U-Bolt Dia.

Torque

(NOM)

Nm

Lbs. Ft.

½

88-109

65-80

5/8

176-217

130-160

¾

271-325

200-240

7/8

305-573

225-275

1

441-543

325-400

WHEELS

Wheel Alignment

To guard against excessive tire wear, have the front wheel alignment inspected occasionally by your IH Dealer for tow-in, camber and

axle caster.

WHEEL-CAST

On cast type wheels, the rim clamp nuts should be inspected at regular intervals to see that they are tight. The rim and tire

alignment, in relation to the wheel, should also be inspected to be sure that the tire is running true. Keep the rim clamp bolts tight.

Refer to torque chart for nut size and torque.

RIM AND CLAMP NUT TORQUE

Bolt Size

Torque Newton Meters

½ -13

108-122 Nm (80-90 ft. lbs.)

5/8-11

217-237 Nm (160-175 ft. lbs.)

¾ -10

237-258 Nm (175-190 ft. lbs.)

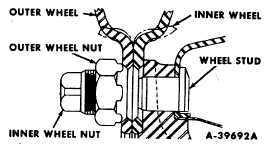

WHEELS-DISC (Dual Wheel Nut)

1.

Mounting faces of the hub, wheel and nut must be free from dirt or excess paint. Mounting faces which have been damaged

from wear or abuse must be repaired or replaced.

2.

Right hand threads are used on the right hand side of the vehicle and left hand threads on the left side.

3.

Tighten the single wheel nuts alternately.

4.

Tighten the wheel mounting stud nuts to 608-675 Nm (450-500 ft. lbs.) torque.

5.

On dual wheels loosen the outer nuts before attempting to tighten the inner nuts. Tighten inner nuts to 675 N

m (500 ft.

lbs.) torque and outer nuts to 608 Nm (450 ft. lbs.) torque. Always tighten the inner nuts 68 Nm (50 ft. lbs.) more than

the outer nuts and never let the outer nuts get below 540 N

m (400 ft. lbs.).

14

|