|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

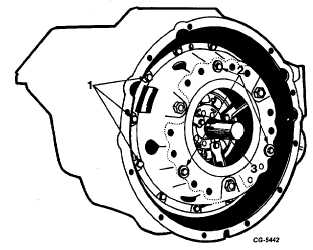

alternately, evenly and securely. Remove the three

retaining bolts and flatwashers which were installed to

hold the clutch compressed, Figure 49.

NOTE: The clutch will not operate properly unless

these retaining bolts and flatwashers are removed.

23. Position a new water pump mounting gasket on the

cylinder block and install water pump.

NOTE: Use a nonhardening sealing compound on the

water pump capscrews and torque to specified

torque.

Fig. 150 Clutch Installation to Flywheel

1. Cover retaining bolts

2. Retaining bolts for compressing clutch

3. Aligning bar

24. Position new cylinder head gaskets (insure the stamped

"Front" is to the front of the engine) on each bank over the

aligning dowel sleeves insuring that all bolt holes in the

gaskets are in line with those on the cylinder block. Place

cylinder head on the proper bank aligning the head with

the dowel sleeves in the crankcase. Loosely install all

cylinder head bolts and flatwashers.

25. Repeat Step 24 for the opposite cylinder head.

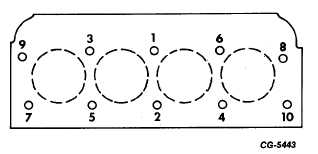

26. Tighten the cylinder head bolts alternately and evenly in

sequence as illustrated in Figure 151 to the torque shown

in the "Torque Chart."

Repeat this operation on the opposite cylinder head. It is

not necessary to retorque the cylinder head bolts after a

run-in period.

27. Install the hydraulic tappets in their respective bores in

the cylinder block.

28. Insert the valve lifter (push) rods in their respective

positions.

29. Place the rocker arms and pivots on their respective

cylinder heads making sure the rocker arms are in line

with the push rods and valves. Install mounting bolts and

tighten to specified torque. See "Torque Chart."

30. Position the intake manifold seals in position in front and

rear of crankcase. See Figure 38.

Fig. 151 Cylinder Head Mounting Bolt Tightening

Sequence

31. Position the tappet cover and intake manifold gasket

assembly on the crankcase. Note the roll pins provided

for proper alignment.

32. Place intake manifold in position making sure the

direction of distributor rotation is located at the front of

the engine. Secure the manifold to the cylinder heads

with bolts and washers. Tighten to specified torque.

NOTE: Use nonhardening sealing compound on bolts

prior to installation. Also, insure that lifting eyes are

installed under the right front and left rear bolts.

33. Place the cylinder head cover gaskets in each cover and

install the cylinder head cover with the oil filler cap on the

right cylinder head securing with screws and washers.

Repeat this operation for opposite cover.

CGES-210 Page 61

PRINTED IN UNITED STATES OF AMERICA

|