|

| |

TM5-4210-229-14&P

6-15.

TRANSMISSION REPAIR (Continued).

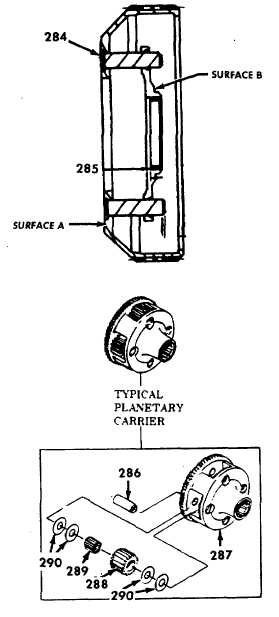

(h) Using a lathe with a four jaw chuck, mount

the carrier with surface A facing the chuck.

Insert the six fabricated dummy pins (284)

into the pinion pin holes. Adjust the chuck,

centering the carrier based on surface B

and the runout of the dummy pins (284).

(i) Total runout of the bushing (285) after

boring must not exceed 0.002 inch (0.05

mm).

NOTE

The

hydraulic

press,

used

with

planetary rebuilding set, should have a

ten ton (9000 kg)capacity, an adjustable

press bed of 25 inches (64 cm)

minimum opening and a pressure

gauge to assist in determining proper

installation and staking of the pinion

pins.

(j) Using a drill that is slightly smaller than the

pinion pin (286) diameter, drill into the

swaged ends of the pins (only one end

required). Do not drill into the carrier. The

rear ends of all pinion pins except those in

the center carrier assembly will be drilled.

Drill the front ends of the center assembly

pins.

(k) Place press fixture in a hydraulic press.

Select the proper spacer and adapter, if

required, from the special tool chart.

Position these parts (if used) to support the

carrier assembly (drilled ends of pinion

pins upward) solidly on the press fixture.

(I) Install pin remover into the ram of the

press fixture. Press the pinion pins (286)

from the carrier assembly (287).

(m) Remove the pinion groups, consisting of

pinions (288), bearings (289) and thrust

washers (290).

(n) Lubricate needle rollers (289) and thrust

washers (290) with oil-soluble grease

(Appendix D, Item 21) before assembling

the pinion groups. Assemble all of the

pinion groups for the carrier assembly

(287).

Each

group

is

assembled

by

inserting-the proper loading pin into the

bore of the pinion, installing the needle

roller bearings around the loading pin,

installing a steel thrust washer at each end

of the pinion, and installing a bronze thrust

washer onto each steel thrust washer.

(o) Position the carrier assembly (287) rear

end upward (except the center carrier).

Install all pinion groups into the planetary

carrier, aligning the loading pins with the

pin bores in the carrier.

6-76

|