|

| |

TM5-4210-229-14&P

Section XXIV. MAINTENANCE OF STEERING ASSEMBLY

Para.

Drag Link Replacement........................................... 4-178

General ................................................................... 4-175

Para.

Pitman Arm Replacement....................................... 4-176

The Rod Replacement............................................ 4-177

4-175. GENERAL.

This section contains information the maintenance of the steering assembly components that are maintainable at

the Organizational level.

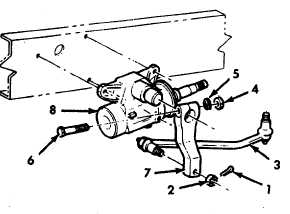

4-176. PITMAN ARM REPLACEMENT.

This task covers:

a. Removal

b. Installation

Initial SET-UP

Tools

General Mechanics Tool Kit

Materials/Parts

Pitman Arm (488704C1)

General Safety Instructions

Engine OFF.

Transmission in (N) neutral.

Parking brake set.

Battery selector switch OFF.

REMOVAL

a.

Remove cotter pin (1) from the attaching nut (2).

b.

Remove nut (2).

c.

Remove the drag link (3) from the pitman arm.

d.

Remove the nut (4) and lockwasher (5) from the

pinch bolt (6) that secures the pitman arm

(7) to

the steering gear (8) sector

shaft.

e.

Drive wedge into slot in pitman arm (7). Remove

pitman arm (7).

INSTALLATION

a.

Position the pitman arm (7) on the sector shaft,

aligning the timing mark on the sector shaft to the

timing mark on the pitman arm. Use the pinch bolt (6)

to align the groove on the sector shaft and the bolt hole

in the pitman arm (7).

b.

Remove the wedge, making certain that the pitman

arm (7) stays aligned to the sector shaft.

c.

Install lockwasher (5) and nut (4) and torque nut (4)

to 330-370 ft-lb (447-502 N.m).

d.

Install ball stud of drag link (3) into the pitman arm

(7).

e.

Install nut (2) and torque to 110-125 ft-lb (149-169

N.m).

f.

Install cotter pin (1).

NOTE

If cotter pin cannot be installed after obtaining

minimum torque, do not back off nut. Tighten to next

castellation.

4-192

|