|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-224-14 & P

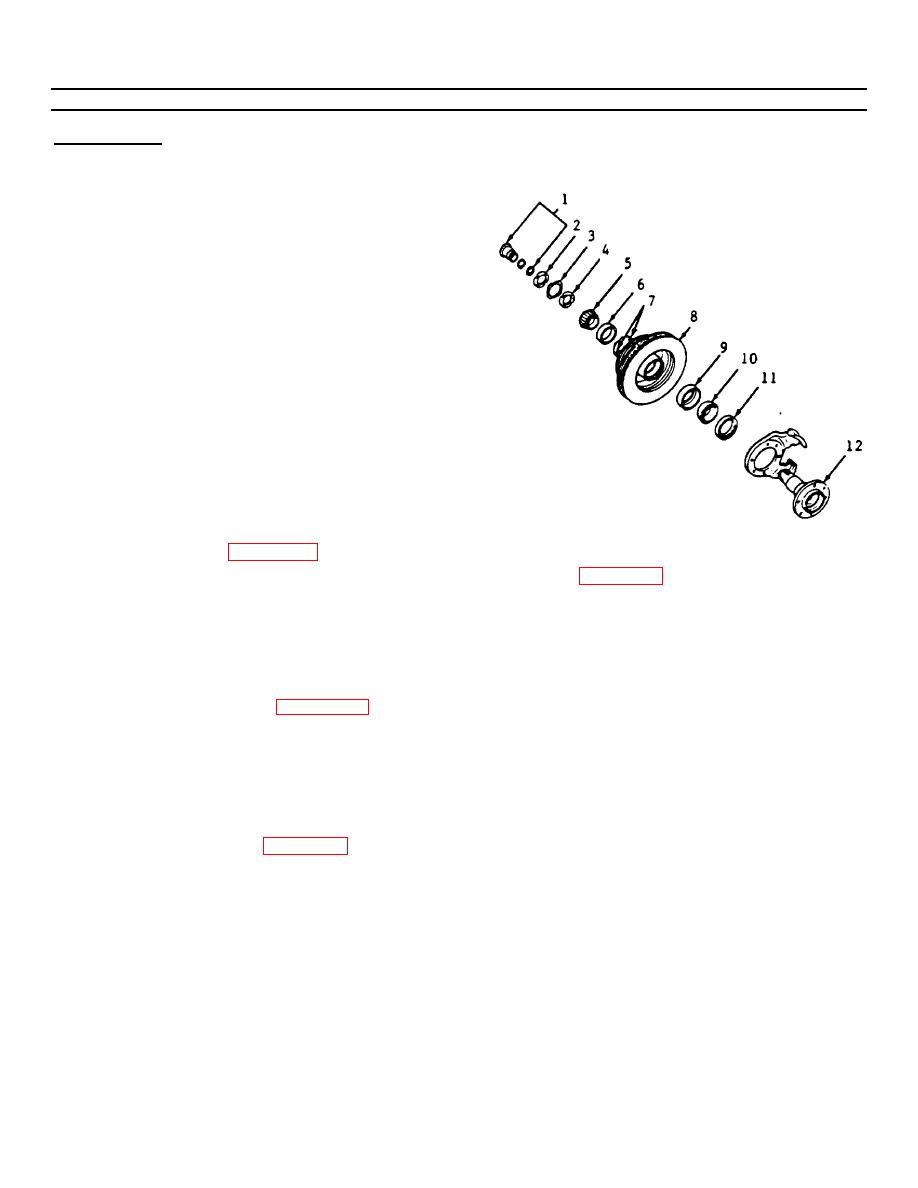

4-233. WHEEL HUB/ROTOR REPLACEMENT. (Continued)

d. Put a small quantity of grease inboard of each wheel

INSTALLATION

bearing cup, inside the rotor/hub (8).

CAUTION

Do not damage the hub/rotor

during the race installations.

a. Install races (4 and 9) into the rotor/hub (8).

Use the driver handle and bearing race installer

(outer) for installation of the outer bearing outer

race (6). Use the driver handle and bearing

race installer (inner) for installation of the inner

bearing inner race (9).

WARNING

Cleaning

solvent,

Federal

Specification P-D-680, is both toxic

and flammable. Keep off skin.

Use only in a well-ventilated area

and avoid prolonged breathing of

vapors. Keep away from open

flame.

b. Clean the grease from the rotor/ hub (8), spindle

(12), and wheel bearings (5 and 10) using

cleaning solvent (Appendix D, Item 44) and a

e. Fill the wheel bearing (cone and roller assemblies)

small brush with no loose bristles.

full of grease (Appendix D, Item 15)

WARNING

CAUTION

Do not spin the wheel bearings

Failure to completely pack the

with compressed air to dry them as

wheel bearings (cones, rollers and

the wheel bearings may be

cage) with grease will result in

damaged.

Be certain to use an

premature wheel bearing damage

approved high temperature front

and/or wear.

wheel bearing grease (Appendix D,

Item 15).

NOTE

Use a cone-type grease packer

NOTE

that forces grease into the bearing.

Do not mix greases as mixing may

If a cone-type grease packer is not

change the grease's properties

available, pack the bearings by

resulting in poor performance.

hand.

If packing the wheel

bearings by hand, work the grease

c. Apply a thin film of grease (Appendix D, Item 15) to

into the bearings between the

the spindle (12) at the outer wheel bearing seat and at

rollers, cones and the cage.

the inner wheel bearing seat and at the shoulder and

seal seat.

f. Install the inner wheel bearing (10) into the

rotor/hub (8).

4-326

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |