|

| |

TM 5-4210-220-34

2-21.

FRONT AXLE - Continued

2-21.2

Differential Carrier - Continued

(1)

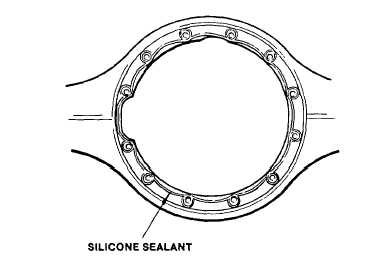

Apply a 1/8 in. (3 mm) bead of silicone

sealant (item 28, Appendix B) to mounting

flange on axle housing as shown.

(2)

Ensure shift fork (7) is to the side, away

from the differential, and the sliding clutch

is engaged.

(3)

Install

differential

carrier

(11)

in

axle

housing (4) using lockwashers, nuts (9),

and capscrews (8). Tighten nuts to 240 ft

lb (325 Nm). Tighten capscrews to 220 ft lb

(300 Nm).

(4)

Push left and right wheel end assemblies

(3) into axle housing (4). Turn pinion yoke,

if necessary, to line up and engage axle

shaft and differential side gears. Attach

wheel

ends

to

axle

housing

using

lockwashers, nuts (2), and capscrews (1).

(5)

Tighten nuts to 360 ft lb (490 Nm) and tighten capscrews to 220 ft lb (300 Nm).

(6)

Install axle breather (10).

(7)

Install differential lock air shift unit as detailed in TM 5-4210-220-12.

(8)

Install brake air lines, if removed, between frame and wheel-end-mounted brake air chambers.

(9)

Install and adjust tie rod end (6) and steering drag link on left wheel end as detailed in TM 5-4210-220-12.

(10) Remove maintenance trestles and, with truck resting on the floor, tighten pinion shaft yoke nut (12) to 960 ft

lb (1300 Nm).

REPAIR

a.

Differential, Differential Lock, and Ring Gear Repair

NOTE

If ring gear and pinion are considered reuseable, check tooth contact pattern and ring gear backlash

before disassembling differential carrier. See ADJUSTMENT following. Best results are obtained when

established wear patterns are maintained in used gearing. Before disassembling differential carrier, the

effectiveness of the differential lock should be checked.

(1)

Mount differential carrier assembly in a repair stand.

(2)

Remove shift fork seal and spring (53). Remove expansion plugs (54) and drive out shift fork shaft (55).

2-288

|