|

| |

TM 9-254

Section VII. SAFE STORAGE OF LOOSE PARTS

3-15.

General.

During disassembly and assembly operations, temporary preservation procedures are required in order to protect parts

from contamination and corrosion Small loose parts from units that are disassembled should be kept in a plastic storage

container. Larger assemblies should have all openings covered with lens paper, and sealed with tape to prevent entrance

of airborne dirt and moisture.

3-16.

Storage Containers.

a.

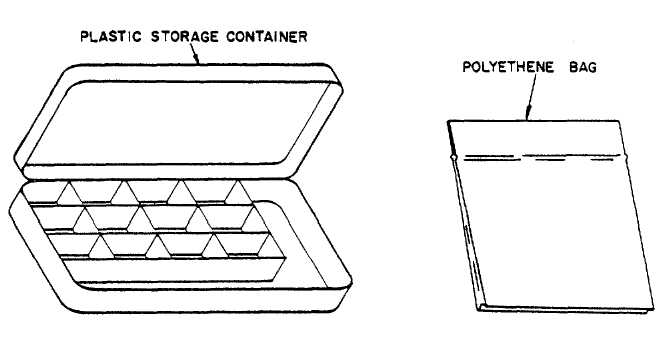

Plastic Storage Container (fig. 3-44). When units are being disassembled, loose parts from these units

should be placed in plastic storage containers in a logical order of disassembly. Use a separate storage container for each

assembly or subassembly and label each tray.

(1)

Use plastic storage containers with a top if available, to keep loose parts separate and in order so that

reassembly may be made easier.

(2)

If mechanical parts are to be stored in the trays for a few days before assembly, do not remove the old

grease. A perfectly clean metal will corrode.

(3)

Optics which are being held for inspection or installation should be covered with lens paper and sealed in

polyethylene bags.

(4)

Store the plastic storage containers containing parts in a safe area where they will not be lost or knocked

over.

b.

Polyethylene Bags (fig. 3-44). If plastic storage containers are not available, store loose parts in various sizes

of polyethylene bags. Label bags to indicate order of disassembly.

Figure 3-44. Storage Containers for loose parts

3-42

|