|

| |

TM 9-254

3-13.

Using Expendables - Continued

(5)

Before greasing a bearing, it must first be cleaned of all dirt, oil, and grease. To clean the bearing,

completely immerse it in cleaning solvent and agitate the bearing back and forth.

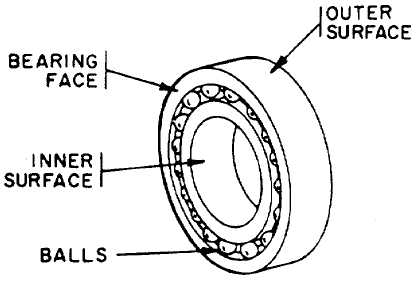

Figure 3-36. Applying Grease to Bearing

(6)

Remove bearing from the cleaning solvent. Blow dry using low-pressure air or allow it to air dry

completely before applying grease.

(7)

Using fingers, apply grease to the balls of the bearing and press the grease into the spaces between the

balls.

(8)

Turn the bearing over and apply grease as described in step (7) to the opposite side of the bearing.

Rotate bearing to distribute grease evenly.

(9)

Use a clean, dry cloth to remove excess grease from the bearing.

CAUTION

Use care when lubricating beaded seals that are made of metal plates and contain rubber like

gaskets. Grease should be applied only to the very top of gasket and not to the sides.

NOTE

In steps (10) and (11), refer to figure 3-37.

(10) Apply a thin film of grease only to the top of the gaskets (fig. 3-37).

NOTE

There is a gasket located on both sides of the metal plate as shown in figure 3-37.

3-35

|