|

| |

TM 9-254

3-7.

Worm and Worm Gear Mechanisms - Continued

g.

Chatter. A chattering movement is usually an indication of a tight ball cap (fig. 3-15). If adjustment of the

socket and ring does not cure the trouble without producing excessive backlash, the trouble is elsewhere.

(1)

The ball may be out-of-round or the socket and seat may not be properly lapped in.

(2)

The plunger spring (fig. 3-15) may be too tight or the worm not lubricated.

(3)

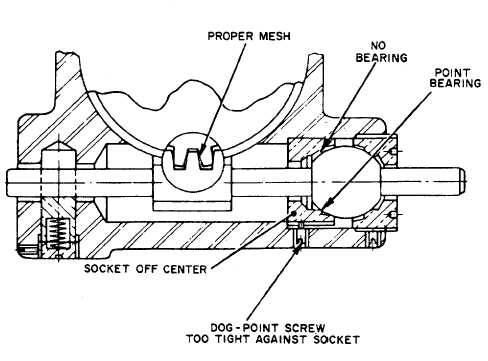

The dog-point screw, which keeps the ball socket from turning in the housing, may be too tight against

the socket (fig. 3-22). The socket should be a slip fit in the housing. When the ball cap is brought

against the ball, the socket will center itself on the ball, unless the dog-point screw or pin prevents it

from doing so. When the socket is placed in the housing, see that the dog-point of the screw or pin is in

the groove in the socket and that the socket is not binding in the housing. After the ball cap has been

properly adjusted against the ball, adjust the dog-point screw until it touches the socket and then back it

out about 1/4 turn. If the screw is tight against the socket, it is forcing the socket off center, thereby,

producing a rough or chattering movement.

Figure 3-22. Dog-Point Screw Tight Against Socket

3-19

|