|

| |

TM 9-254

3-7.

Worm and Worm Gear Mechanism - Continued

(5)

After lapping has been completed, remove the worm gear mechanism from the housing. Thoroughly

wash all parts in cleaning solvent to remove the lapping compound. Place the wormshaft in a lathe and

increase the radius on the corners of the worm thread. This is done to allow the worm to move into

proper mesh as the movement wears.

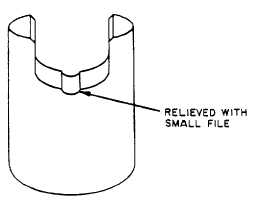

Figure 3-16. Point of Relief for Plunger

f.

Backlash.

(1)

Backlash is one of the main factors contributing to the malfunctioning of the moving mechanical parts in

fire control instruments. It is free play or movement of the driving member without corresponding

movement of the driven member. The total absence of backlash is the ideal condition for fire control

instruments. It is well known, however, that small amounts of backlash must be present in order to

obtain smoothly functioning and operable mechanical movements. Tolerance limits for backlash have,

therefore, been established for the various instruments. These limits can be found in the pertinent

technical manuals and rebuild standards. There are many causes for backlash. The most prevalent are

looseness in gear meshes, end play in shafts, side play in bearings, and binding in bearing surfaces. In

many cases it will be found that total backlash is a result of a combination of these causes.

(2)

The inspection for backlash in fire control instruments is primarily a means for determining the angular

distance through which the driving member (worm) of a mechanism moves before causing movement of

the driven member (worm gear). The types of mechanisms usually encountered are azimuth

mechanisms, elevation mechanisms, angle-of-site mechanisms, and cross-leveling mechanisms.

(3)

Looseness in gear meshes is a type of backlash due to the slack or looseness between the mating

members of a mechanism. To use the example of the worm and worm gear, a close mesh of the worm

with the teeth of the worm gear is obtained by means of pressure against the wormshaft from a spring

and plunger (fig. 3-15). If the teeth are not firmly in mesh, there may be rotation of the worm without a

corresponding movement of the worm gear. This condition may be due to a weak plunger spring which

does not force the worm all the way in or which permits it to ride out instead of turning the worm gear

(fig. 3-17).

3-15

|