|

| |

TM 9-254

3-1.

Tapered Pins and Tapered Holes - Continued

e.

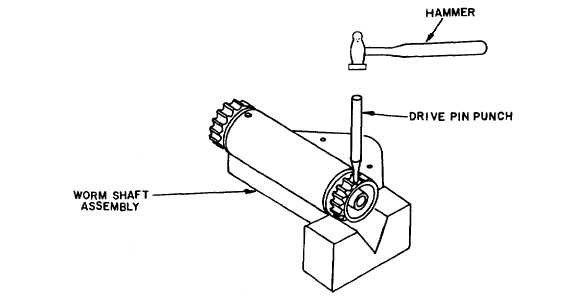

Installation of Tapered Pin (fig. 3-3). To install a tapered pin, first be sure that the hole is properly lined up as

outlined in paragraph d above. A clean hole and a well machined pin should fit together within one-sixteenth of an inch of

the final position. If this is not true, check the pin for burrs and the hole for poor alinement of parts. Support work with a V-

block and position tapered pin into knob of worm shaft assembly. Place the flat tip of a drive pin punch over the exposed

end of the tapered pin. Give one sharp tap on the end of the drive pin punch with a hammer to set the tapered pin. Check

to insure that the tapered pin has seated properly and the knob is securely fastened to shaft. If tapered pin protrudes

through the hole, file off excess pin until it is flush with the surface.

Figure 3-3. Installing a Tapered Pin In a Wormshaft Assembly

f.

Removal of Tapered Pin (fig. 3-3). To remove a tapered pin, look to determine which is the smaller of the two

ends. Support the work on a V-block with smallest end facing up. Select a drive pin punch slightly smaller in diameter

than the small end of the pin. Place the flat tip of a drive pin punch against the small end of the pin and strike the punch

one sharp blow using a hammer. Such a blow will usually remove the pin, whereas several haphazardly struck blows will

damage the end of the pin Determine the size of the hammer according to the size of the job.

3-2.

Reconditioning Damaged Tapered Holes.

When the tapered hole has become damaged because of reasons previously outlined, the hole must be reconditioned

before a pin can be installed. The reconditioned hole and the new pin will, in most cases, be one size larger because of

the material removed from the hole. As in the case of a new hole, the repair will involve drilling and reaming. Line up the

tapers of both parts and secure the assembly on the drill press with the hole perpendicular to the drill press table. Select

the proper size drill that will be necessary to provide a hole of the next larger size. Check the drill for centering in the hole

and drill. Ream out the hole with the proper size tapered reamer. Check to see how far the pin drops into the hole, then

touch up the hole with the reamer until the pin seats properly. If tapered pin protrudes through the hole, file off excess pin

until it is flush with the surface.

3-3

|