|

| |

TM 9-254

CHAPTER 3

GENERAL MAINTENANCE PROCEDURES

Section I. DRILLING AND REAMING FOR TAPERED PINS

3-1.

Tapered Pins and Tapered Holes.

a.

General. A tapered pin (fig. 3-1) may be defined as a metal rod with a diameter that decreases uniformly.

Tapered pins are used to secure one part to another in a positive relation to each other, such as the securing of a knob to

a shaft.

Figure 3-1. Assortment of Tapered Pins

b.

Numbering System. All tapered pins are tapered similarly (1/4 in. per ft.) and certain diameters are identified

with numbers. All pins with the same number would then have the same maximum diameter; therefore, the longer the pin

(of any one number), the smaller the minimum diameter.

c.

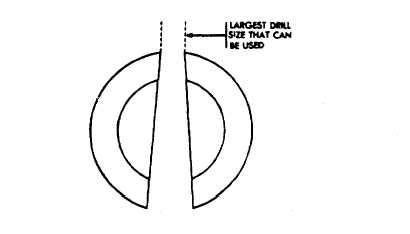

Preparation of Parts to Receive Tapered Pin. When preparing parts to receive a tapered pin, a hole must be

drilled and then reamed with a tapered reamer. The larger the drill used, within the scope of the taper, the less reaming

will be required. Before drilling any hole for a tapered pin, it is necessary to know the minimum diameter of the pin to be

used so that a drill may be selected accordingly. Refer to figure 3-2 and table 3-1 for selecting the proper drill size

required for a tapered hole. When the proper drill size has been determined, the hole should be drilled and then reamed

with a tapered reamer of the correct number.

Figure 3-2. Selection Drill for Tapered hole

3-1

|