|

| |

TM 9-254

4-25.

Thread Chasers.

a.

Purpose. Thread chasers are used to rethread damaged external or internal threads.

b.

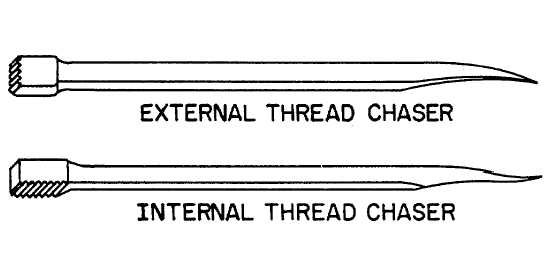

Types of Thread Chasers. Thread chasers (fig. 4-53) are threading tools that have several teeth. These

tools are available to chase threaded parts having standard threads. The internal thread chaser has its cutting teeth

located on a side face. The external thread chaser has its cutting teeth on the end of the shaft. The handle end of the tool

shaft tapers to a point.

Figure 4-53. Thread Chasers

c.

Use of Thread Chasers. Select the proper thread chaser for the job. You must know the number of threads

per inch on the work. Simply use a rule to measure off a distance of one inch and count the number of threads in the

measured distance. If screw pitch gages are available, use them to determine the number of threads per inch. Secure the

work in a vise or hold the work in one hand. Hold the chaser in the other hand and run it around the threaded section.

Hold the chaser firmly so that the cutting teeth are parallel to the threads in the work as shown in (fig. 4-54). The cutting

action will follow the previously cut threads and restore the damaged portion.

d.

Care of Thread Chasers. Never attempt to sharpen thread chasers yourself. This is a highly specialized

cutting process which involves precision work on hard tool steel of a shape altogether not suited for simple stroking on an

oilstone. Store chasers carefully when not in use. Coat with a light film of oil and store individually so that the cutting

edges do not touch other metal. For long periods of storage, coat chasers with a rust-preventive compound and store in a

dry place.

4-57

|