|

| |

TM 9-254

4-17. Printed Circuit Board - Continued

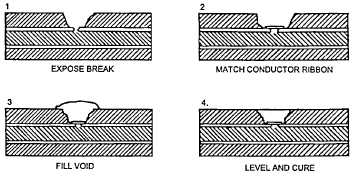

Figure 4-44.6. Damaged Conductor (Trace) Repair

(a)

Fill the void with a compatible epoxy mixture and allow to cure after the welding is completed.

(b)

Level the cured epoxy mixture with a chisel or mill to match the surface finish of the printed circuit board.

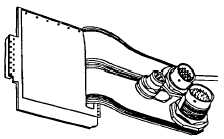

m. Flexible Circuits. Flexible circuits/cables are designed to provide efficient and practical methods for making

connections and utilizing space. The etched circuit is composed of flat copper conductors enclosed in insulating

materials The conductor to, Isolation bonding provides a barrier against moisture and gases, and is very durable. The

product may be bent, coiled, twisted, and formed to follow the various outlines of multiple systems. Assemblies may

be hinged, pulled-out and flexed for maintenance or inspection even when still in operation. Flex circuitry/cables

provide high reliability with less distortion or noise than conventional wiring. in addition, various methods can be used

for final assembly, such as, welding and soldering.

Figure 4-44.7. Flexible Circuit

l. Multiwire Technology. A multiwire PWA/PCB is a computer tape controlled series of conductor wires laid down on

an adhesive coated double-sided printed circuit board. The two sides of the board are used for voltage and ground

plane applications The voltage and ground planes are etched to both sides providing a semicured base for laying in

the conductor wires. The circuit is formed by using a pressure head, that imbeds the conductor wires in the adhesive.

Holes are then drilled in the board followed by the plating of these holes. Multiwire PWA/PCBs can be hand, wave, or

dip soldered using conventional soldering techniques. Multiwire printed circuit boards are recommended for high

frequency applications.

m. Additive Plating Technology. Additive plating may be defined in this manner: Additive plating is a process

whereby printed circuit boards are manufactured by selective depositing of a conductor material on an unclad base

material (no conductor material anyplace on the base material). The circuit is developed by applying a background

negative-image resist pattern, which leaves conductor areas and holes to be plated through, exposed for metal

deposit. Additive plating is an economy oriented process.

n. Leadless Components. A new trend in the manufacture of PCBs is to use so-called "LEADLESS COMPONENTS."

These are passive components such as resistors or capacitors which are made on semiconductor substrate material

and are greatly reduced in size. They do have axial leads, however, and are removed and replaced in a similar

manner to flat pack ICs (para 4-17.k.1). Use of leadless components can reduce a multilayer board to a single layer

and reduce its size by as much as one third.

4-46.4 Change 6

|