|

| |

TM 9-254

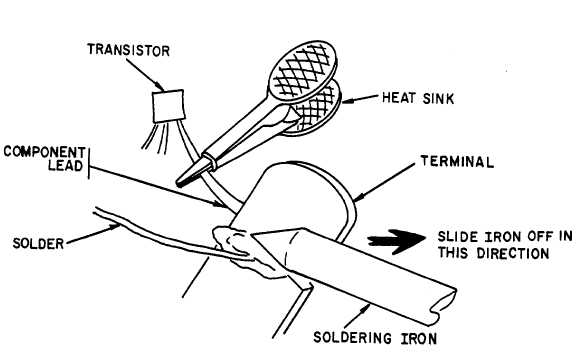

Figure 4-25. Applying Solder

(5)

Cooling. After the solder has been applied to the joint, the connection should not be moved or have

stress applied to it during cooling. Never use any kind of liquid to cool a soldered connection, it should

always be air cooled.

(6)

Flux residue removal. Flux residue should be removed within one hour after soldering. The best

method for removal of flux residue is to dip a medium stiff bristle brush in alcohol and rub solder joint

until all residue is removed.

(7)

Inspection. Inspect solder joint for defects such as not enough solder, too much solder, and cold solder

joint. If resoldering is required, the same procedure should be followed as described in steps (1)

through (6) above. A cold solder joint or disturbed joint will require only reheating and reflowing of the

solder. The final step of any soldering operation should always be flux residue removal as described in

step (6) above.

4-30

|