|

| |

TM 9-254

4-8.

Types of Scribers.

a.

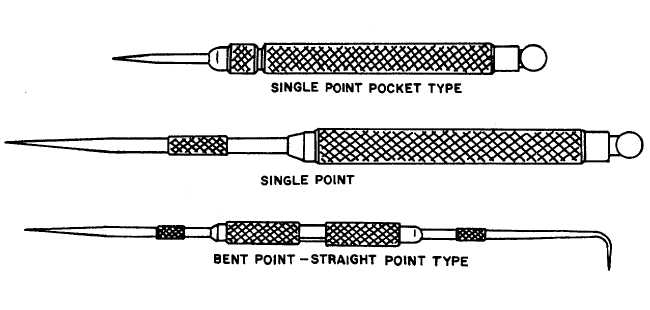

Machinist’s Scribers (fig. 4-20). Machinist’s single point pocket-type scribers have a scriber point made of

tempered high grade steel and a handle of steel tubing that is nickel plated The point is reversible, telescoping into the

knurled handle when not in use. This type scriber usually has a 1/4 or 3/8 inch diameter handle with a point length of 2-3/8

or 2-7/8 inches. Bent point scribers are usually 8 to 12 inches long with one straight point, and one long or one short bent

point. Some of these scribers are threaded and can be engaged in either end of the handle. The long bent point is

designed for reaching through holes beyond a lip or ridge.

Figure 4-20. Types of Machinist’s Scribers

b.

Tungsten Carbide Scribers. These scribers are used to lay out lines on very hard materials, such as

hardened steel and glass. The scriber point is made of tungsten carbide, a long wearing material, which makes it possible

to scribe sharp, well defined lines on the hardest materials. Some of these scribers are used with an extension in

conjunction with a vernier height gage, which allows reverse measurements, to be taken from the top of the bottom side of

the gage jaw. This type scriber is hardened, ground, and lapped to a point so that a line or series of lines may be drawn

and spaced as required in laying out of dies, and so forth.

4-9.

Using the Scriber.

a.

Sharpness. Make sure the point of the scriber is sharp. To sharpen, rotate the scriber between the thumb

and forefinger while moving the point back-and forth on an oilstone.

b.

Work Surface. Clean work surfaces of all dirt and oil.

c.

Steel Rule. Place a steel rule or straight edge on the work beside the line to be scribed.

d.

Holding the Scriber. Use the fingertips of one hand to hold the rule in position and hold the scriber in the

other hand as you would a pencil (fig. 4-21).

4-24

|