|

| |

TM 750-116

(2) Optical System.

(a)

2-5.a.

(b)

(c)

(d)

(e)

Perform purging and charging procedure para

Relief valve should open between 3-10 psig.

Purge instrument at 7 psig for 5 minutes.

Ensure relief valve closes between 1-5 psig.

Leak test for minimum of 5 minutes.

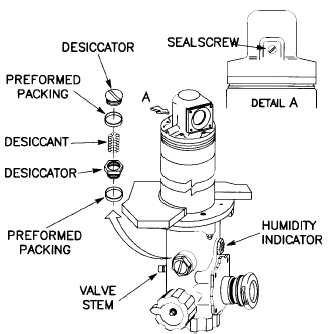

h. Panoramic Telescope, M901A1 (fig. 3–76).

NOTE

Purge panoramic telescope when the internal

optical surfaces are fogged over. Replace the

desiccant and two preformed packings every

time the unit is purged. Do not attempt to check

the pressure in the panoramic telescope at any

other time than during the pressurization cycle.

Loss of pressure resulting from such attempts

will shorten the time between maintenance

actions.

(1) Remove desiccator by unscrewing container part

(hex head) from telescope body.

(2) Hold container part upright and remove slotted cap

of desiccator.

(3) Discard old desiccant. Discard two preformed

packings from desiccator. Install desiccator.

Figure 3-76 Panoramic Telescope, M901A1

(4) Close nitrogen tank valve and pressure regulator

valve.

3-32

Contamination can damage the telescope.

Blow pressurized nitrogen through the

charging lines to remove contamination.

(5) Open tank supply valve and observe high pressure

gauge indicating that tank is pressurized.

(6) Remove lockwire and cap from valve stem.

The sealscrew is a captive screw and must

not be removed. Removal of the screw dam-

ages equipment.

(7) Install hose assembly on valve stem and loosen

setscrew.

(8) Adjust pressure regulator to 4-5 psig (28 to 34

kPa) as indicated on low pressure gauge.

(9) Verify nitrogen is being vented from sealscrew

hole and observe humidity indicator.

(10) Purge telescope until all sections of indicator are

blue. During purge, lubricate preformed packings lightly

with silicone compound.

(11) Close pressure regultor valve and tighten set-

screw.

(12) Remove dessicator from telescope body and refill

desiccator to level slightly below threads.

(13) Lightly lubricate preformed packing on top part

of desiccator with grease or silicone compound.

(14) Install top part of desiccator to bottom.

(15) Lightly lubricate preformed packing with grease

or silicone compound.

(16) Install desiccator on telescope body and tighten

to 20 to 30 in lb. (2.25 to 3.39 Nm).

(17) Slowly open pressure regulator valve and charge

instrument to 2.0 + or - .0.5 psig (14 + or - 3 kPa). Tighten

setscrew when pressure regulator gauge stabilizes.

(18) If overpressurization occurs, slowly open set-

screw, adjust pressure regulator to 2.0 + or - 0.5 psig; then

tighten setscrew when pressure regulator gauge stabilizes.

(19) Close pressure regulator gauge. Remove hose

assembly and replace cap on nut of valve and install lock-

wire.

(20) Close tank supply valve and verify on high pres-

sure gage.

|