|

| |

3-6

TM 750-116

NOTE

Some early manufacture boresight inlet ports

were equipped with metric threads. To attach the

hose asembly to these units, it is necessary to use

the 10-32 adapter supplied with the purging kit.

Insert the adapter carefully and do not force the

adapter past its binding point.

(2) Perform purging procedure para 2-5.d.

(3) Purge instrument at 5 psig for 5 minutes.

(4) Install the rubber protective head cover on the

boresight.

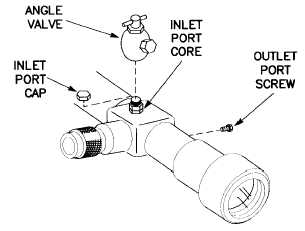

b. M26A1/M27A1 Muzzle Boresight (fig. 3-12).

Figure 3-12 M26A1/M27A1 Muzzle Boresight

(1) Release pressure from optical unit by removing

pneumatic inlet port cap and depressing valve core .

(2) Attach hose assembly to angle valve (special tool,

TM9-4933-259-14&P) and install angle valve on inlet

port.

(3) Turn angle valve T clockwise (CW) until snug.

(4) Perform purging and charging procedure para

2-5.b.

(5) Purge instrument at 5 psig for 5 minutes or until

all traces of moisture in optical unit are removed.

(6) Charge instrument at 3 psig maintaining pressure

for 10 seconds.

(7) Turn angle valve T counterclockwise (CCW) until

snug.

(8) Remove hose assembly and angle valve from inlet

port core.

(9) Leak test for minimum of 5 minutes.

3-8. MOUNTS, TELESCOPE.

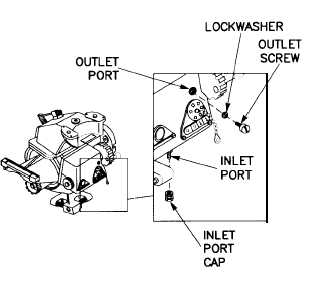

a. Telescope Mount, M137 (fig. 3-13).

Figure 3-13 M137 Telescope Mount

(1) Perform purging procedure para 2-5.c.

(2) Purge instrument at 5 psig for 5 minutes.

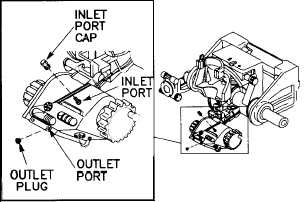

b. Telescope Mount, M145/M145A1 (fig. 3-14).

Figure 3-14 M145/M145A1 Telescope Mount

(1) Perform purging procedure para 2-5.c.

(2) Purge instrument at 5 psig for 5 minutes.

|