|

|||

|

|

|||

|

Page Title:

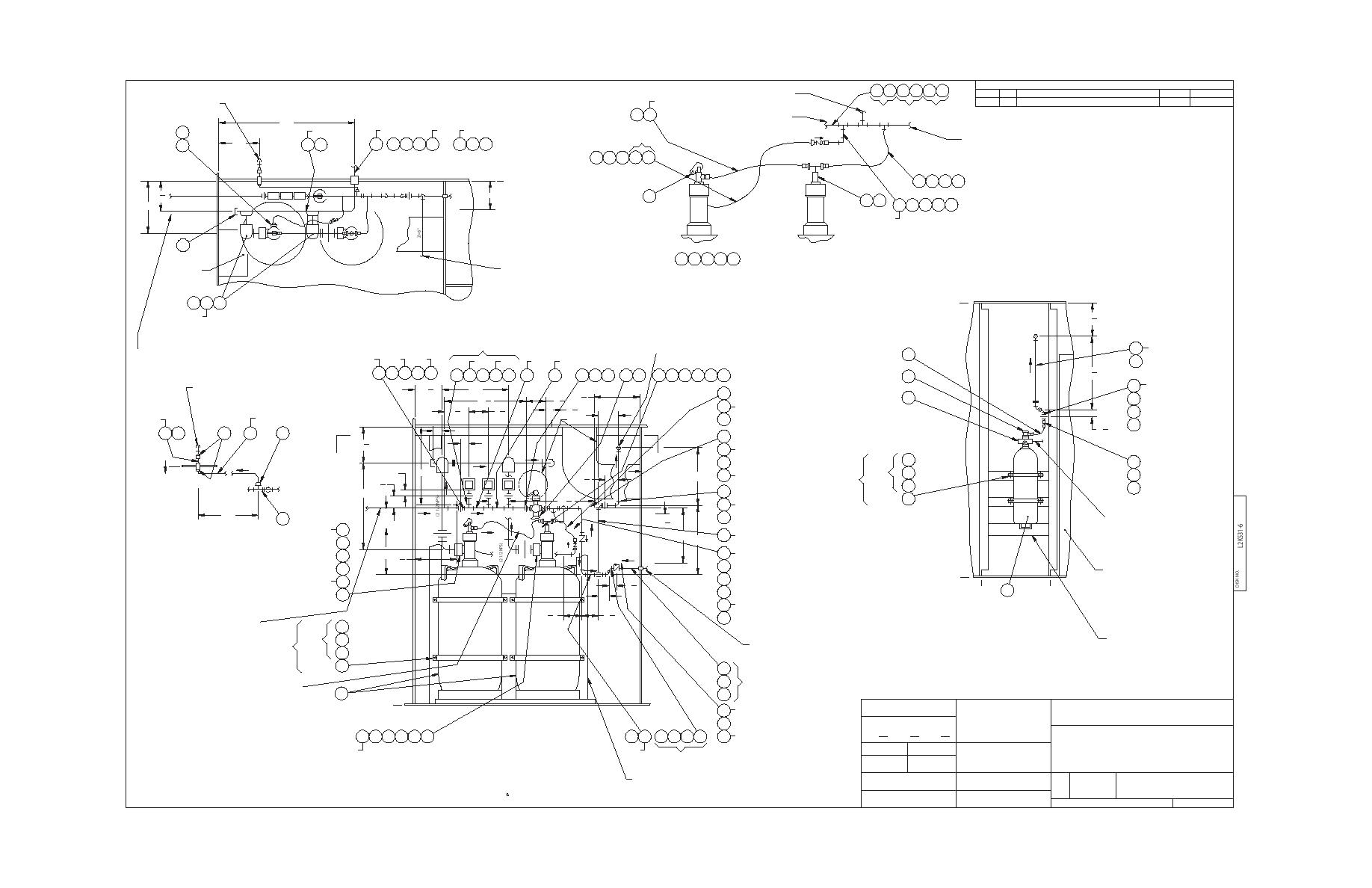

FM-200 SYSTEM PIPING INSTALLATION AND DETAILS |

|

||

| ||||||||||

|

|

TM55-1905-243-24&P

REVISION

21 22

21 22

21 22

ACTUATION PIPING TO

APPROVED

DESCRIPTION

DATE

ZONE

REV

48-B

350LB SLAVE CYLINDER IN TUNNEL

Actuation Hose Arrangement Corrections

5/23/01

J. Back

44-C

A

SEE VIEW

2 REQD

REF

REF

REF

51 49

1/2 NPS CO2 ACTUATION PIPING

47''

CONTD FROM CO2 CYLINDER

1/2 NPS CO2 VENT PIPE

0/4/3

51

REF

REF

3/6/0

CONTD TO WEATHER DECK

REF

2

223 88 222 221

213 88 223

14''

2

3

50

34 35 36 51 50

51 49 34 36

BHD 42 1/2

1''

48

10''

(10

)

38 230

2

21 27 24 37 36

2X 18''

0/4/0

LOCAL NOTE:

A: FM-200 GAS FROM MASTER CYLINDER ADAPTER KIT PRESSURIZES THE HOSE DURING A DISCHARGE.

VENT

THE FM-200 GAS GOES THRU THE CHECK VALVE THRU THE TEE, AND INTO THE CO2 ACTUATION PIPING.

B: THE CHECK VALVE STOPS CO2, OR SLAVE CYLINDER FM-200 GAS FROM CHARGING THE MASTER

52

CYLINDER ADAPTER KIT.

C: GAS FROM A MANUAL 600LB CYLINDER ACTIVATION IN THE AC GEN ROOM WILL FIRE THE

34 35 36 37 27

350LB SLAVE CYLINDER IN THE TUNNEL. MANUAL ACTIVATION OF THE 350LB SLAVE CYLINDER

1/2 NPS CO2 VENT PIPE

IN THE TUNNEL WILL ALSO FIRE THE 2 600LB CYLINDERS IN THE AC GEN ROOM.

ELECTRICAL

VIEW 44-C

CONTD TO WEATHER DECK

CABLEWAY

INSTALLATION OF FM-200 CYLINDER

ACTUATION HOSE

VIEW 47-C

NOT TO SCALE

56

6 55

01 LEVEL

ENGINE ROOM FM-200 SYSTEM

1''

0/7/2

PIPING INSTALLATION AND DETAILS

(11 )

2

A/C AND EMERGENCY GENERATOR ROOM

BHD 42 1/2

1/2 NPS CO2 VENT PIPE

ITEMS NOT SHOWN

3 PLACES

CONTD TO WEATHER DECK

21

2/1/2

67

1/2 NPS CO2 ACTUATION PIPING

OMITTED FOR CLARITY

27

0/3/0

0/5/2

0/7/0

0/4/1

0/2/0

0/6/3

0/7/0

CONTD FROM CO2 CYLINDER

1''

21 25 21 27 21

25

22 21 25 21 57

21

21

25 24 58

59 60

58 24 25 24 22 24

65

2

0/2/2

21

CO2 ACTUATION TUBE

1''

9

23''

22

2

3''

CONTD TO TUNNEL (STBD SIDE)

64

15

27

1''

1''

4

28

7

SEE CO2 ACTUATION TUBING TABLE

4

21

2

0/9/0

3''

3''

1''

2

24

C

8

6

4

L

4

2

7''

22

BEND AS REQD

VENT

0/4/0

27

01 LEVEL

1''

2

4''

21 151

198

197

198

2

27

C

47

1''

3''

12

21

Z=6''

2

2/3/0

47

(3 NPS)

151

25

46

2 REQD

2 REQD

28''

3X 2''

24

21

0/2/3

3''

20''

4

FOR CO2

1''

4

45

3X 4

25

CYLINDER

4

223

2X 30''

63

3''

29

7''

221

4

1/8/0

(1/2 NPS)

36''

223

ENGINE ROOM FM-200 SYSTEM

22

1''

REF

7

7''

ACTUATION CABLE CONTD

2

6

2/0/0

221

2/0/0

19''

TO MACHINERY CASING

24''

43

VIEW 48-B

SEE ACTUATION CABLE TABLE

21

0/7/2

42

16''

1''

INSTALLATION OF FM-200 CYLINDER

14

2

27

ACTUATION TUBE

41

EMERGENCY

Z=49''

FOR REMOTE CYLINDER

MAIN DECK

24

SWITCHBOARD

6

0/7/0

1''

SCALE 1/4''=1'-0''

3

61

4

155

FR

FR

40

ITEMS NOT SHOWN OMITTED FOR CLARITY

3''

48

47

21

1/4/0

1''

3''

42-B

5

7

27

VIEW

2

4

1/2 NPS CO2 ACTUATION PIPING

(39-C)

47

CONTD FROM CO2 CYLINDER

ENGINE ROOM FM-200 SYSTEM

2 REQD

FOR CO2 CYLINDER

46

2 REQD

FOR FM-200

1/2 NPS CO2 VENT PIPE

PIPING INSTALLATION AND DETAILS

FOUNDATION AND MOUNTING

CYLINDER

45

A/C AND EMERGENCY GENERATOR ROOM

CONTD FROM A/C AND EMER

50-C

2 PLACES

ANGLES

SEE VIEW

GEN RM CO2 SYSTEM

LONG BHD 48'' OFF C

44

L

21

LOOKING OUTBOARD

ITEMS NOT SHOWN OMITTED FOR CLARITY

155

REF

FOR INSTALLATION OF

1

24

REF

FM-200 CYLINDER ACTUATION HOSE

44-C

CONTRACT NUMBER

MAIN DECK

SEE VIEW

UNLESS OTHERWISE SPECIFIED

U.S. ARMY TANK AUTOMOTIVE COMMAND

21

1/7/2

DIMENSIONS ARE IN INCHES

DTRSXX-XX-X-XXXXX

WARREN, MICHIGAN 48397-5000

46-A

27

VIEW

TOLERANCES ON:

CONTRACTOR

3 PLACES

ANGLES

2 PLACES

(39-C)

U.S. ARMY LCU-2000

XXX

6

41 42 43 42 40

213 21

24 27 24 27

21

1/7/0

ENGINE ROOM FM-200 SYSTEM

DRAWN BY

DATE

RPE (FP) CLASS APPROVAL

FM-200 SYSTEM

2/6/0

0/5/3

PIPING INSTALLATION AND DETAILS

BO

06/17/98

PHILIP DINENNO

A/C AND EMERGENCY GENERATOR ROOM

REF

CHECKER

ENGINEER

STATE OF TENNESSEE

PIPING INSTALLATION AND DETAILS

BHD 42 1/2

JAS

TR

LIC. NO. 015882

LOOKING FWD

CLASS DESIGN APPROVAL

AS BUILT DRAWING

FOR FM-200 CYLINDERS FOUNDATION

SIZE

CAGE CODE

MARK GENTILE

M. CAPUTO 8/1/03

ITEMS NOT SHOWN OMITTED FOR CLARITY

55-A

LCU-2000-5553-1

D

19207

SEE VIEW

CLASS DRAWING APPROVAL

AS BUILT CHECKED

ROTATED 90 CCW

FO-6

M. GENTILE 8/8/03

MARK GENTILE 4/28/99

SHEET

6 OF 28

SCALE

FP-11/(FP-12 blank)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |