|

|||

|

|

|||

|

Page Title:

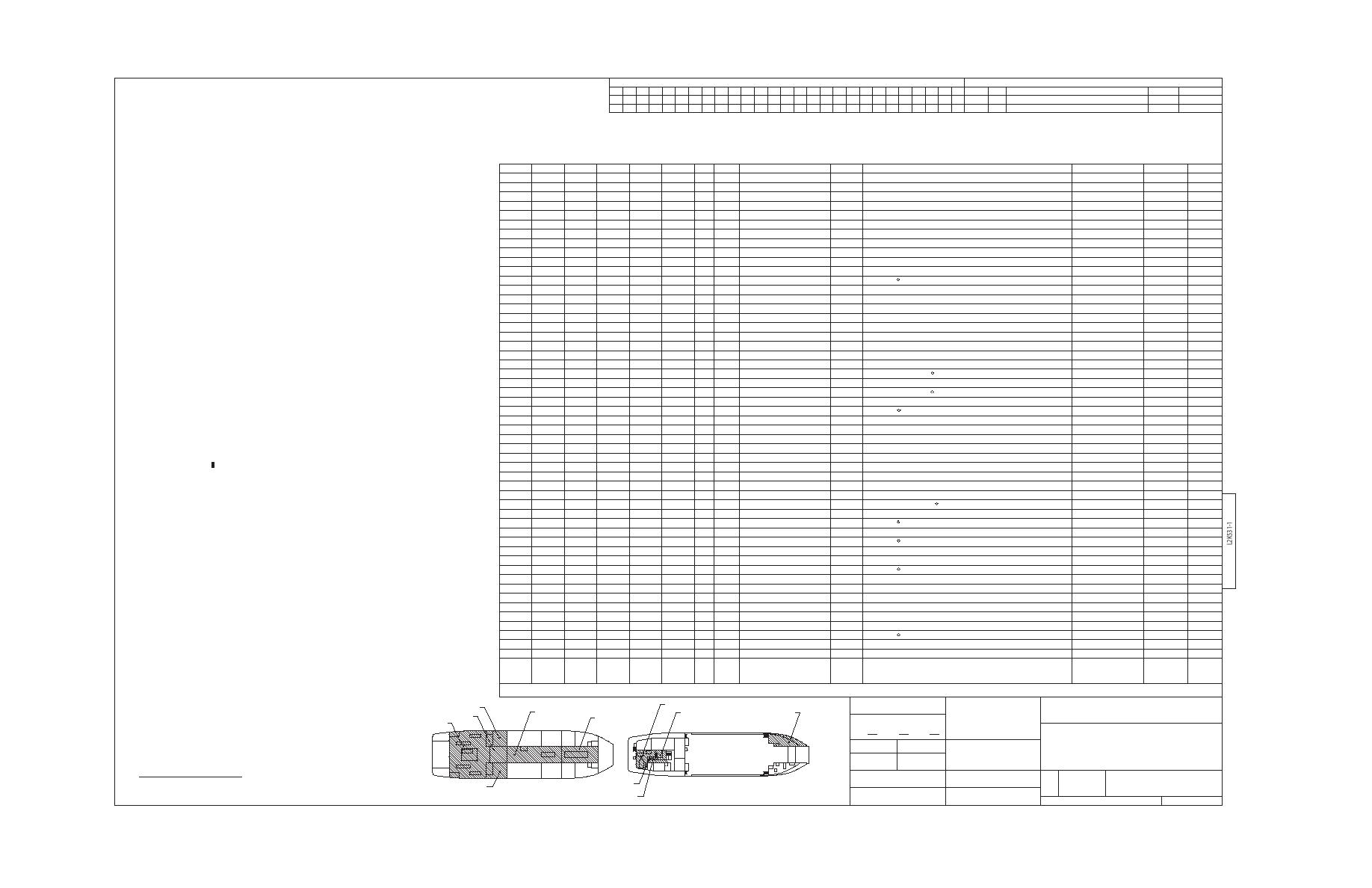

FM-200 SYSTEM PIPING INSTALLATION AND DETAILS |

|

||

| ||||||||||

|

|

TM55-1905-243-24&P

STATUS OF REVISION

SHEETS

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

DESCRIPTION

DATE

APPROVED

ZONE

REV

NOTES:

X

Actuation Hose Arrangement Corrections

5/23/01

J.Back/HughesAssoc.

44-C

A

X

X

X

PAINT LOCKER SYSTEM REDESIGN

11/19/01

E.FORSSELL/HughesAssoc.

B

X

X

1. THIS DRAWING HAS BEEN DEVELOPED AS A DETAILED DESIGN/INSTALLATION

DRAWING FOR THE INSTALLATION OF FM-200 FIRE SUPPRESSION SYSTEM

ON THE U.S. ARMY LANDING CRAFT UTILITY, 2000 CLASS (LCU-2000).

2. ALL WORK SHALL BE PERFORMED UTILIZING GOOD COMMERCIAL PRACTICES

AND SHALL SATISFY THE STANDARDS, REGULATIONS, REQUIREMENTS, AND

(PARTS LIST CONTINUED ON SHEET 2)

RECOMMENDED PRACTICES OF THE CODE OF FEDERAL REGULATIONS (CFR),

ASME B16.3

CAP, THD, CL 300, 3 NPS, GALV

52

MI

1 EA

1 EA

8.40

THE STATEMENT OF WORK ASSOCIATED WITH THIS CONTRACT, AND THE

IDA54

264986

3 EA

1 EA

2 EA

1 EA

1 EA

COML (KIDDE)

ACTUATION HOSE, 30'' L

51

8 EA

1.00

FOLLOWING DRAWINGS AND INSTALLATION SPECIFICATION:

844895

2 EA

1 EA

1 EA

50

COML (KIDDE)

IDA54

BRASS

0.50

MASTER CYLINDER ADAPTER KIT

FM-200 SYSTEM PIPING INSTALLATION AND DETAILS

LCU-2000-5553-1

3 EA

2 EA

3 EA

2 EA

2 EA

49

COML (KIDDE)

IDA54

6992-0501

BRASS

0.50

CONNECTOR, MALE, 5/16'' FLARE X 1/8 NPT

12 EA

LCU-2000-5553-2

FM-200 SYSTEM MISCELLANEOUS MODIFICATIONS

1 EA

1 EA

LEVER/PRESSURE OPERATED CONTROL HEAD

IDA54

878751

2 EA

COML (KIDDE)

48

1.00

FM-200 SYSTEM ELECTRICAL MODIFICATIONS

LCU-2000-5553-3

8 EA

4 EA

7 EA

4 EA

8 EA

12 EA

43 EA

ASME B18.2.2

47

-

NUT, HEX, 1/2-13 UNC-2B, GRADE 8, ZINC PL

STEEL

FM-200 SYSTEM LABEL PLATES AND PLACARDS

LCU-2000-5553-4

4 EA

7 EA

4 EA

8 EA

8 EA

12 EA

43 EA

46

ASME B18.21.1

-

WASHER, LOCK, HLCL SPR, RGLR, 1/2 NOM, ZINC PL

STEEL

WWS PIPING INSTALLATION AND DETAILS

LCU-2000-5231-1

4 EA

7 EA

4 EA

8 EA

8 EA

12 EA

45

SCREW, CAP, HEX HD, 1/2-13 UNC-2A X 2'' L,

43 EA

STEEL

ASME B18.2.1

B1821BH050C200N

0.03

WWS LABEL PLATES AND PLACARDS

LCU-2000-5231-2

FM-200/WWS INSTALLATION SPECIFICATION

LCU-2K-97-5553-SPEC

GRADE 8, ZINC CTD

44

2 EA

4 EA

6 EA

STRAP, CYLINDER, 600 LB

COML (KIDDE)

7.00

STEEL

IDA54

294651

3. ANY DEVIATIONS IN ROUTING OF SYSTEM PIPING OR NUMBER OF FITTINGS

43

1 EA

2 EA

3 EA

UNION, THD, CL 300, 2 1/2 NPS, GALV

ASME B16.39

MI

7.50

SHALL BE APPROVED BY THE DESIGN ENGINEER, REGISTERED ENGINEER (FP),

42

2 EA

10 EA

7 EA

1 EA

NIPPLE, THD, CLOSE, 2 1/2 NPS, GALV

ASTM A 733

STEEL

1.21

AND THE GOVERNMENT CONTRACTING ACTIVITY PRIOR TO INSTALLATION.

41

3 EA

5 EA

2 EA

ELBOW, 90 , THD, CL 300, 2 1/2 NPS, GALV

ASME B16.3

MI

7.20

40

2 EA

3 EA

VALVE OUTLET ADAPTER, 2 1/2 NPS

283906

1 EA

COML (KIDDE)

IDA54

BRASS

6.00

4. PIPING MUST BE REAMED FREE OF BURRS AND RIDGES AFTER CUTTING, WELDING,

39

ASTM A 36

1.40

ANGLE, 1 1/2 X 1 1/2 X 1/4 STK, 7'' L

STEEL

1 EA

1 EA

OR THREADING. ALL THREADED JOINTS SHALL CONFORM TO AMERICAN NATIONAL

38

1 EA

1 EA

1 EA

4 EA

STANDARD TAPER PIPE THREADS IN ACCORDANCE WITH ASME B1.20.1. JOINT

PRESSURE OPERATED CONTROL HEAD

1 EA

COML (KIDDE)

1.00

IDA54

878737

BRASS

COMPOUND OR THREAD TAPE SHALL BE APPLIED ONLY TO MALE PIPE THREADS,

37

2 EA

3 EA

1 EA

ASME B16.14

BUSHING, HEX HD, THD, 1/2 TO 1/4 NPS, GALV

MI

0.10

EXCLUDING THE FIRST TWO THREADS.

NIPPLE, THD, CLOSE, 1/4 NPS, GALV

3 EA

36

1 EA

2 EA

ASTM A 733

STEEL

0.03

3 EA

35

1 EA

2 EA

VALVE, CHECK, 1/4 NPS

264985

COML (KIDDE)

IDA54

BRASS

1.00

5. REQUIRED PIPE LENGTHS ARE DISCLOSED AS ''XX/XX/XX'', REPRESENTING

3 EA

34

BUSHING, HEX HD, THD, 1/4 TO 1/8 NPS, GALV

1 EA

2 EA

ASME B16.14

MI

0.10

FITTING TO FITTING CENTER LINE DISTANCE IN FT/IN/FOURTHS.

33

1 EA

1 EA

1 EA

1 EA

4 EA

BUSHING, HEX HD, THD, 1/2 TO 1/8 NPS, GALV

ASME B16.14

MI

0.10

32

6. ''Z'' DIMENSION REPRESENTS DISTANCE FROM DECK ABOVE TO PIPE CENTERLINE.

1 EA

1 EA

SHEET, 10 GA (.1345), 5" X 12"

ASTM A 569

2.34

STEEL

31

4 EA

4 EA

NOZZLE, DISCHARGE, 360 , 1 1/4 NPS (E2-N1, N2, N3 & N4 ENG RM BILGE)

COML (KIDDE)

1.00

IDA54

90-194026-290

BRASS

7. PIPE HANGERS:

30

2 EA

2 EA

2 EA

6 EA

ASME B16.3

MI

2.60

TEE, THD, CL 300, 1 1/4 NPS, GALV

ALL PIPING SHALL BE SUPPORTED BY PIPE HANGERS TO PREVENT VIBRATION AND PROTECT

29

4 EA

4 EA

1.00

COML (KIDDE)

IDA54

90-194025-313

BRASS

NOZZLE, DISCHARGE, 360 , 1 NPS (E1-N1, N4, N5 & N6 ENG RM BILGE)

AGAINST DAMAGE. PIPE HANGERS SHALL BE DESIGNED TO SUPPORT FIVE TIMES THE WEIGHT

28

4 EA

4 EA

9 EA

17 EA

NIPPLE, THD, CLOSE, 1 1/4 NPS, GALV

0.31

ASTM A 733

STEEL

OF THE PIPE WHEN FILLED WITH WATER PLUS 250 LB. AT EACH POINT OF PIPING SUPPORT.

1 EA

27

20 EA

8 EA

9 EA

5 EA

7 EA

50 EA

ELBOW, 90 , THD, CL 300, 1/2 NPS, GALV

0.50

ASME B16.3

MI

PIPE HANGERS SHALL BE IN ACCORDANCE WITH ASTM F 708 (SEE VIEW 15-A):

26

- STANDOFF: ANGLE, 42'' L

SIREN, PRESSURE OPERATED - REUSE FROM ENG. RM HALON SYSTEM

- LINER: SYNTHETIC RUBBER

- NUTS: NYLOCK OR EQUIVALENT

2 EA

25

9 EA

4 EA

3 EA

3 EA

1 EA

22 EA

MI

ASME B16.39

0.60

UNION, THD, CL 300, 1/2 NPS, GALV

- FINISH: PRIMER

5 EA

24

7 EA

8 EA

2 EA

4 EA

28 EA

2 EA

ASTM A 733

NIPPLE, THD, CL 300, CLOSE, 1/2 NPS, GALV

STEEL

0.08

SPACING OF PIPE HANGERS SHALL BE IN ACCORDANCE WITH TABLE 2, ASTM F 708 TITLED;

2 EA

23

1 EA

1 EA

1 EA

1 EA

6 EA

ASME B16.3

CAP, THD, CL 300, 1/2 NPS, GALV

MI

0.30

PIPE HANGER SPACING. SPACING OF PIPE HANGERS AS DISCLOSED IN THE FIELD OF THE

1 EA

22

6 EA

2 EA

3 EA

3 EA

16 EA

1 EA

ASME B16.3

0.50

MI

TEE, THD, CL 300, 1/2 NPS, GALV

DRAWING BY SYMBOL '' '' ARE FOR GUIDANCE ONLY.

5 FT

21

50 FT

10 FT

15 FT

10 FT

50 FT

PIPE, SMLS, .840 OD X .109 WALL, GALV (1/2 NPS)

ASTM A 53

220 FT

STEEL

0.85

20

36 EA

16 FT

52 EA

COML (McMASTER CARR)

39428

3015T21

1.00

TUBE CLAMP ASSY, DAMPING, VIBRATION, WELD MOUNT, 1/4'' OD TUBE

8. EXISTING INSULATION DISTURBED OR DAMAGED BY THIS INSTALLATION

19

4 EA

1 EA

2 EA

7 EA

ASME B16.3

MI

2.80

COUPLING, RDCR, THD, CL 300, CONC, 2 TO 1 1/2 NPS, GALV

SHALL BE REPLACED OR REPAIRED TO A LIKE NEW CONDITION.

18

2 EA

2 EA

1 EA

5 EA

TEE, THD, CL 300, 2 NPS, GALV

ASME B16.3

MI

5.00

17

2 EA

2 EA

NOZZLE, DISCHARGE, 360 , 1 1/2 NPS (E1-N2, & N3 ENG RM)

COML (KIDDE)

1.00

IDA54

90-194027-413

BRASS

9. ALL WATERTIGHT BOUNDARY PENETRATIONS ABANDONED BY THE REMOVAL OF HALON

FIRE EXTINGUISHING SYSTEMS AND VESSEL MODIFICATIONS SHALL BE WELDED CLOSED.

16

6 EA

2 EA

3 EA

3 EA

1 EA

NIPPLE, THD, CLOSE, 1 1/2 NPS, GALV

0.40

ASTM A 733

15 EA

STEEL

OTHER ABANDONED BULKHEAD, DECK, AND FRAMING PENETRATIONS SHALL BE WELDED

15

2 EA

1 EA

5 EA

1 EA

ELBOW, 90 , THD, CL 300, 1 1/2 NPS, GALV

MI

2.40

ASME B16.3

9 EA

CLOSED AND ALL BRACKETS REMOVED. ALL WELDED FITTINGS SHALL BE GROUND FLUSH,

14

25 FT

50 FT

ASTM A 53

PIPE, SMLS, 1.900 OD X .145 WALL, GALV (1 1/2 NPS)

STEEL

2.72

75 FT

PRIMED, AND PAINTED IN ACCORDANCE WITH TB 43-0144, ''PAINTING OF WATERCRAFT''.

13

3 EA

1 EA

ELBOW, 90 , THD, CL 300, 2 NPS, GALV

2 EA

1 EA

4.00

ASME B16.3

MI

7 EA

12

PIPE, SMLS, 2.375 OD X .154 WALL, GALV (2 NPS)

15 FT

35 FT

ASTM A 53

60 FT

STEEL

3.65

10 FT

10. PRIOR TO PERFORMING FUNCTIONAL TESTING, SYSTEM PIPING INSTALLATION, INCLUDING

11

2 EA

2 EA

1 EA

ASME B16.3

6 EA

MI

3.00

COUPLING, RDCR, THD, CL 300, CONC, 2 TO 1 1/4 NPS, GALV

ALL WELDING, SHALL BE COMPLETE. PRIOR TO INSTALLATION OF DISCHARGE NOZZLES

10

5 EA

14 EA

ELBOW, 90 , THD, CL 300, 1 1/4 NPS, GALV

1 EA

8 EA

1 EA

MI

1.80

ASME B16.3

AND CONNECTION TO CYLINDERS, SYSTEM PIPING SHALL BE CLEANED, BLOWN OUT,

9

60 FT

35 FT

10 FT

ASTM A 53

145 FT

STEEL

2.27

PIPE, SMLS, 1.660 OD X .140 WALL, GALV (1 1/4 NPS)

AND SUBJECTED TO A PNEUMATIC LEAK TEST IN ACCORDANCE WITH 46 CFR 56.97-35

8

4 EA

8 EA

1 EA

3 EA

ASME B16.3

MI

4.40

COUPLING, RDCR, THD, CL 300, CONC, 2 1/2 TO 2 NPS, GALV

(EXCLUDING (F)) AND NVIC 6-72, CHANGE 1, SECTION D.3. THE GAS USED AS A TEST

7

MEDIUM SHALL NOT BE BE FLAMMABLE (NITROGEN OR OTHER INERT GAS). IF CO2 IS USED AS

3 EA

TEE, THD, CL 300, 2 1/2 NPS, GALV

2 EA

1 EA

8.90

ASME B16.3

MI

THE TEST MEDIUM, IT SHALL BE VAPORIZED AND AT AMBIENT CONDITIONS PRIOR TO AND

6

20 FT

PIPE, SMLS, 2.875 OD X .203 WALL, GALV (2 1/2 NPS)

25 FT

ASTM A 53

STEEL

45 FT

5.79

DURING TESTING. TEST PRESSURE SHALL BE 1.5 TIMES THE MAXIMUM SYSTEM WORKING

5

2 EA

ASME B16.3

2 EA

MI

6.60

COUPLING, RDCR, THD, CL 300, CONC, 3 TO 2 1/2 NPS, GALV

PRESSURE AND SHALL BE HELD FOR A MINIMUM OF 10 MINUTES. AT THE END OF 10

4

1 EA

ASME B16.3

1 EA

MI

13.00

TEE, THD, CL 300, 3 NPS, GALV

MINUTES, THE PRESSURE DROP SHALL NOT EXCEED FIVE (5) PERCENT OF THE TEST

3

3 EA

ASME B16.3

3 EA

MI

9.80

ELBOW, 90 , THD, CL 300, 3 NPS, GALV

PRESSURE. FOR SYSTEMS WHERE THE FIVE (5) PERCENT PRESSURE DROP IS EXCEEDED,

2

30 FT

PIPE, SMLS, 3.500 OD X .216 WALL, GALV (3 NPS)

ASTM A 53

30 FT

STEEL

7.58

THE PIPING SHALL BE CHECKED USING SOAPY WATER TO LOCATE LEAKS. EXTREME CAUTION

1

2 EA

90-100601-001

2 EA

CYLINDER ASSY, 600 LB (363 LB / 165 KG FM-200)

COML (KIDDE)

STEEL

IDA54

725.00

SHALL BE USED WHILE THE SYSTEM PIPING IS CHARGED.

IN LIEU OF PNEUMATIC TESTING, SMALL INDEPENDENT SYSTEM PIPING INSTALLATIONS

QUANTITY

QUANTITY

QUANTITY

QUANTITY

TOTAL

UNIT

QUANTITY

QUANTITY

PROTECTING SPACES SUCH AS EMERGENCY GENERATOR ROOMS AND PAINT LOCKERS MAY

FIND

REQUIRED

REQUIRED

REQUIRED

REQUIRED

CAGE

PART OR

QUANTITY

WEIGHT

REQUIRED

REQUIRED

BE TESTED IN ACCORDANCE WITH 46 CFR 95.15-15(J) (4). (BLOWING OUT THE SYSTEM

ENG RM

MCC AREA

PAINT LKR

TUNNEL

BT

EMER GEN

NO.

NOMENCLATURE OR DESCRIPTION

SPECIFICATION

REQUIRED

IDENTIFYING NUMBER

CODE

MATERIAL

(LB)

PIPING WITH AIR AT A PRESSURE OF AT LEAST 100 PSI AND CHECK EACH JOINT FOR

PARTS LIST

LEAKS WITH SOAPY WATER.).

CONTRACT NUMBER

UNLESS OTHERWISE SPECIFIED

A/C AND EMER GEN RM

U.S. ARMY TANK AUTOMOTIVE COMMAND

MACHINE SHOP

DIMENSIONS ARE IN INCHES

DTRSXX-XX-X-XXXXX

11. SYSTEM PIPING, NEWLY INSTALLED MATERIAL AND EQUIPMENT, AND DISTURBED

TUNNEL

ENGINE ROOM

PAINT LOCKER

WARREN, MICHIGAN 48397-5000

MCC AREA

BOW THRUSTER

ACCESS/PASSAGEWAY

AREAS SHALL BE CLEANED, PAINTED, AND MARKED USING DEPARTMENT OF THE

TOLERANCES ON:

CONTRACTOR

ENGINE ROOM

ROOM

2 PLACES

3 PLACES

ANGLES

ARMY TECHNICAL BULLETIN TB 43-0144 ''PAINTING OF WATERCRAFT'' AS A GUIDE.

U.S. ARMY LCU-2000

XXX

12. DRILL HOLE, USING NO. 29 BIT, FOR SCREW, FIND NO. 96.

DATE

DRAWN BY

RPE (FP) CLASS APPROVAL

FM-200 SYSTEM

AM

06/17/98

PHILIP DINENNO

(NOTES CONTINUED ON SHEET 4.)

CHECKER

ENGINEER

STATE OF TENNESSEE

PIPING INSTALLATION AND DETAILS

JAS

TER

LIC. NO. 015882

DISTRIBUTION STATEMENT A.

CLASS DESIGN APPROVAL

AS BUILT DRAWING

SIZE

CAGE CODE

M. CAPUTO 8/1/03

M. GENTILE

APPROVED FOR PUBLIC RELEASE;

CG LOCKER

D

19207

LCU-2000-5553-1

STOREROOM

CLASS DRAWING APPROVAL

AS BUILT CHECKED

DISTRIBUTION IS UNLIMITED.

MAIN DECK

BELOW MAIN DECK

STOWAGE LOCKER

M. GENTILE 4/28/99

M. GENTILE 8/8/03

SHEET

1 OF 28

SCALE

1''=1'-0''

FO-1

FP-1/(FP-2 blank)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |