DRAFT

TM 5-4210-249-13&P-2

0131

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

TFFT03643

WARNING

ICON 10

Stay clear of equipment ladder rack area unless equipment ladder rack is locked in

raised position or in fully lowered position with POWERED EQUIPMENT RACK

MASTER switch in OFF position. Failure to comply may cause injury or death to

personnel.

NOTE

Front and rear ladder rack motors operate independently from one another. If either motor

operates to a point of binding, actuator arm may begin to make an audible ratcheting

noise.

Clutch ratcheting of ladder rack drive motor actuator is normal operation.

Front and rear ladder rack drive motors are a matched set. If motors do not move at same

speed, it may be necessary to replace both motors as a set.

Step 34.

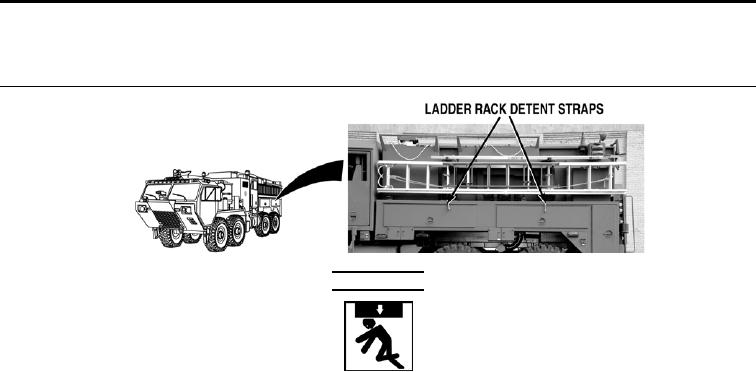

Pull ladder rack detent straps and release (WP 0011). Put POWERED EQUIPMENT

RACK LIFT switch to DOWN position (WP 0004). Check if front and rear ladder rack

motors operate equipment ladder rack to lowered position.

If both front and rear equipment ladder rack motors do not operate, go to

Step 40.

Step 35.

Put POWERED EQUIPMENT RACK LIFT switch to UP and back to DOWN position

(WP 0004). Check if either front or rear equipment ladder rack actuator motors operate

equipment ladder rack to lowered position.

If both equipment ladder racks operate, fault corrected.

Step 36.

Remove ladders from equipment ladder rack (WP 0011). While an assistant pulls non-

operating ladder rack detent strap and holds (WP 0011), put POWERED EQUIPMENT

RACK LIFT switch to DOWN position (WP 0004). Check if non-operating ladder rack

actuator motor operates equipment ladder rack to lowered position.

If non-operating equipment ladder rack does not operate to lowered

position, go to Step 38.

0131-27