|

| |

TM 5-4210-233-14&P-1

5-40. FRONT STEERING AXLE-Continued

(17)

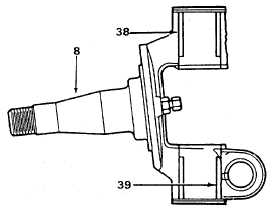

Place the knuckles (8) in a press with at least

5 ton (4500 kg) capacity. Install fabricated tool

in top bushings (38) and press top bushings

from knuckles bores. Repeat for bottom

bushings (39).

39.

b.

Cleaning and Inspection.

WARNING

• Dry cleaning solvent P-D-680 is potentially dangerous. Avoid

repeated and prolonged breathing of vapors and skin contact

with the liquid. Do not use near open flame, arcing equipment or

other ignition sources. Always wear eye protection and

protective clothing. The flash point of P-D-680 is 100 to 138 deg.

F (38 to 59 deg. C).

• Death or serious injury could occur if compressed air is

directed against the skin. Do not use compressed air for

cleaning

or

drying

unless

the

pressure

is/has

been

reducedto30psi(2.11 kg/cm2) ) or less. When working with

compressed air, always use chip guards, eye protection, and

other personal protective equipment.

(1) Clean all metal parts in dry cleaning solvent and use compressed air to dry thoroughly.

(2) Apply a light film of engine oil (OE) (Item 20, Appendix E) to parts after drying. Place parts on

clean cloth or container until ready for assembly.

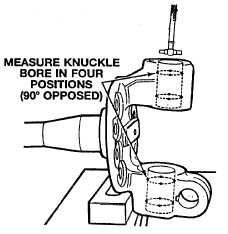

(3) Use a micrometer and telescoping gauge to.

measure inside diameter of knuckle bore. Measure at

two positions at the center line of the side of the

knuckle.

(4) Knuckle bore dimension should be not more

than 2.127 inch (54.025 mm). If dimension exceeds

specifications, replace knuckle.

5-239

|