|

| |

TM 5-4210-233-14&P-1

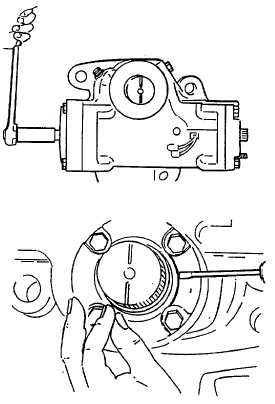

5-39. STEERING GEAR

This task covers:

a.

Disassembly

d.

Adjustment

b.

Cleaning and Inspection

e.

Follow-on Maintenance

c.

Assembly

TOOLS REQUIRED:

EQUIPMENT CONDITION

Tool Kit, General Mechanics, Automotive

Main Engine Shutdown (see para 2-12.)

(Appendix B, Section III, Item 1)

APU Shutdown (see para 2-16.)

Batteries Disconnected (see para 4-114.)

MATERIALS/PARTS REQUIRED:

Steering Gear Removed (see para 4-161.)

Grease High Temperature (Item 15, Appendix E)

Tape, Masking (Item 52, Appendix E)

SPECIAL TOOLS REQUIRED:

Grease, Wheel Bearing (Item 53, Appendix E)

Compression Tool

O-rings (Fig. 158, Appendix F)

(Appendix B, Section III, Item 83)

Teflon washer (Fig. 158, Appendix F)

Seal Installation Tool

Seals (Fig. 158, Appendix F)

(Appendix B, Section III, Item 84)

Retainer (Fig. 158, Appendix F)

Bearing Mandrel

Vent Plug (Fig. 158, Appendix F)

(Appendix B, Section III, Item 88)

Gasket (Fig. 158, Appendix F)

Seal Driving Tool

Solvent, Dry cleaning (Item 3, Appendix E)

a.

Disassembly.

CAUTION

Clamp

only

against

housing

mounting bosses or attach a plate to

the

mounting

bosses

for

this

purpose. Do not clamp against the

body of housing.

(1) Position the steering gear firmly in a vise

with the gear's worm shaft/input shaft (1) in a

horizontal direction. Prepare for fluid

drainage and unplug fluid line ports. Rotate

worm shaft/input shaft with a wrench,

through the gear travel several times to

purge hydraulic fluid from the unit. Then

position the timing mark located on the end

of the sector shaft (2) to a vertical direction.

5-216

|