|

| |

TM 5-4210-233-14&P-1

5-22. BLOWER REPAIR

This task covers:

a.

Disassembly

c.

Assembly

b.

Cleaning/inspection

d.

Follow-on Maintenance

TEST EQUIPMENT

MATERIALS/PARTS REQUIRED

None

Oil, lubricating (Item 10, Appendix E)

Adhesive-sealant, silicone (Item 35, Appendix E)

TOOLS REQUIRED

Solvent, dry cleaning (Item 3, Appendix E)

Tool Kit, General Mechanics, Automotive

Tags, identification (Item 32, Appendix E)

(Appendix B, Section III, Item 1)

Cloth, crocus (Item 34, Appendix E)

Grease, automotive and artillery (Item 1, Appendix E)

Shop Equipment, Automotive

Emery Cloth (Item 25, Appendix E)

Maintenance and Repair

Gaskets (Figure 95, Appendix F)

(Appendix B, Section III, Item 4)

Oil Seal (Figure 95, Appendix F)

Seal Rings (Figure 95, Appendix F)

Tool set, blower service (Appendix B, Section III, Item 14)

Gage set, piston (Appendix B, Section IIII, Item 15)

EQUIPMENT CONDITION

Blower Removed (see para 5-21.)

a.

Disassembly.

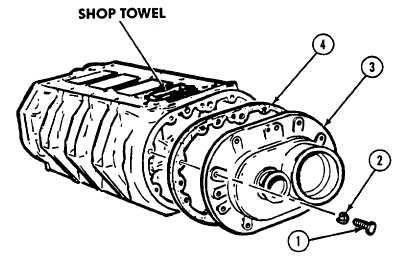

NOTE

To keep gears from turning, place clean folded shop towel

between blower rotors.

(1) Remove ten screws (1), lockwashers (2), rear end plate cover (3), and gasket (4). Discard gasket.

5-123

|