|

| |

TM 5-4210-233-14&P-1

4-143. TIRES AND RIMS - Continued

(2) Mount wheel or inner dual wheel over studs.

Adjust height of wheel lift truck, so damage

does not occur to threads on studs.

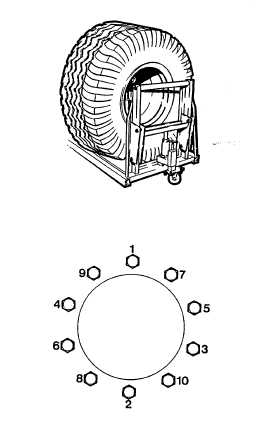

(3) Snug up nuts alternately in sequence shown.

DO NOT tighten them fully until they have

been seated.

CAUTION

Insufficient mounting torque can allow wheel

movement and breakage at low mileage. Exces-

sive mounting torque can cause stud breakage,

bolt hole chamfer burns and disc cracks in the bolt

hole area.

(4) Tighten nuts fully, using the same alternating

sequence. Torque nuts to 450-500 ft-lbs

(612-680 N.m).

(5) Repeat steps 2-4 for outer dual wheel.

IMPORTANT

After the first 50 to 100 miles (80 to 160 km) of service, recheck

torque on wheel nuts, including inner cap nuts on duals. When

inner cap nuts are retighten, be sure to first loosen outer cap

nuts several turns, tighten inner cap nuts and retighten outer cap

nuts. Reset to recommended torque levels.

(6) Raise truck with hydraulic jack and remove jack stands.

(7) Lower jack until truck is supported on its tires. Remove jack and chocks.

c.

Follow-on Maintenance.

(1) Connect batteries (see para 4-114).

4-415

|