|

| |

TM 5-4210-233-14&P-1

SECTION III. OPERATOR MAINTENANCE PROCEDURES

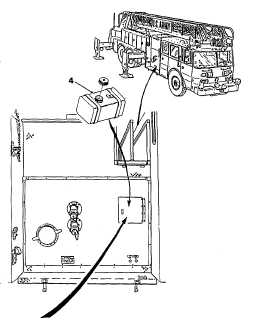

3-3. PRIMING TANK

This task covers:

a. Inspection

b. Service

MATERIAL/PARTS REQUIRED:

EQUIPMENT CONDITION

Oil, SAE 40 (Item 20, Appendix E)

Main Engine Shutdown (see para 2-12 .)

Oil, SAE 5W (Item 59, Appendix E)

APU Shutdown (see para 2-16 .)

Oil, SAE 5W-20 (Item 60, Appendix E)

Batteries Disconnected (see para 4-114 .)

a.

Inspection.

(1)

Check that tank (4) is securely mounted and not corroded or

leaking.

CAUTION

Do not enlarge either hole referred to in step (2).

(2)

Check that hole in filler cap (1) and hole in top of elbow (2)

in priming tank are not plugged. Open (clean) holes, if

plugged.

(3)

Check that gasket (3) in filler cap (1) is in place and not

damaged or deteriorated.

b.

Service.

NOTE

At temperatures above 40°F, use same weight and type of oil

(SAE 40) used in truck engine.

At 0°F or below, use 5W or SAE 5W-20 engine oil in primer

tank. Heavier oils are not suitable at low temperatures.

(1)

Remove filler cap (1) and check oil level in tank (4).

(2)

Add oil as necessary.

3-22

|