|

| |

TM 5-4210-233-14&P-1

5-66. APU GENERATOR-Continued

WARNING

Be careful when working on or with electrical equipment. Do not

be misled by the term "low voltage". Voltages as low as 50 volts

may cause death.

(18) With the end cover and band removed

to allow access to the rig, start the unit.

(19) Apply full rated load.

(20) Allow unit to reach full operating

temperature.

(21) Inspect brushes; they must be seated

across the brush face if we are to have

an accurate setting.

(22) Connect a voltmeter across the dc

terminals.

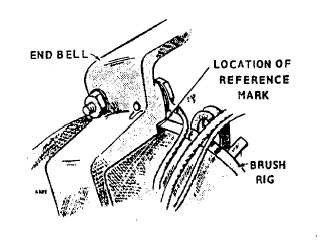

(23) Loosen the brush rig mounting screws

and rotate the rig to get the highest

voltage with full load.

(24)

Rotate the rig in one direction until the

voltmeter reading starts to decrease.

Mark this point.

(25) Repeat Step 20 in the other direction. Half the distance between the two marked points is the

neutral position.

(26) Shutdown unit.

f.

Adjustment.

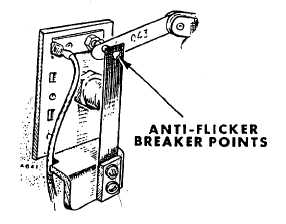

(1) The anti-flicker breaker points are located

on the left rear corner of the engine

crankcase. The camshaft opens these

points on every power stroke to add a

resistor in series with the generator field

windings (2). To adjust the points, crank

the engine until the points are at full

separation. Adjust the stationary contact

to .025 in. (.64 mm) gap. Retighten and

check the gap. When breaker plunger

guide and O-ring are removed, dip O-ring

in oil before reinstalling. Tighten guide to

25 to 28 ft Ibs (34 to 38 N·m).

(2) The adjustable flicker resistor is located

on the right side of the control box. If

flicker becomes excessive, adjust the

resistor by moving its slider. Adjust

resistor for minimum flicker with the

average load on the plant.

g.

Follow-on Maintenance.

(1)

Install APU (see para 4-207).

5-369

|