|

| |

TM 5-4210-233-14&P-1

5-66. APU GENERATOR - Continued

(4)

Remove all brush springs (9) and lift the AC brushes (10) from their holders (11).

(5)

Hold both the end bell (12) and frame assembly (13) since they are separate parts, and remove them

as one assembly from the adapter (14). Screwdriver slots in the adapter provide for prying the frame

loose. Be careful not to let the frame assembly rest or drag on the armature.

(6)

Remove air scroll (15) from adapter (14).

(7)

Turn armature through-stud nut (16) and washer (17) out to the end of the through stud (18).

(8)

While pulling the armature (19), outward with one hand, strike a sharp end-wise blow on the nut with a

heavy soft-faced hammer to loosen the armature. If the armature does not come loose, strike the

armature with a sharp downward blow in the center of the lamination stack with a lead or plastic

hammer. Rotate the armature and repeat. Be careful not to hit the collector rings, commutator,

bearing or windings.

(9)

Upon disassembly, all parts should be wiped clean and visually inspected.

b.

Cleaning.

(1)

Clean and inspect all mating surfaces. Surfaces should be free of nicks and dirt.

(2)

Clean mating area between the generator shaft and the engine crank shaft with a thin film of

lubricating oil Molycoat (Item 61, Appendix E), or equal.

c.

Inspection.

(1)

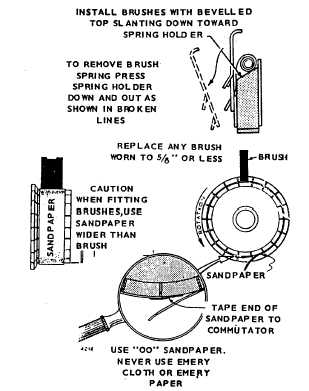

Brushes. To examine the brushes, remove

the end bell band and cover if not already

disassembled. Replace the brushes when

they wear to the Onan name and part

number. At this point there is about 5/8 in.

(16 mm) of brush remaining. If the brush is

not replaced, the slip rings or commutator

will be damaged. All brushes must have at

least a 50 percent seat. If they don't, sand

as illustrated.

(2)

Commutator And Collector Rings. The

commutator must be clean and in good

condition. If it is dirty, clean with paper or

cloth. Do not use a cleaning solvent

because it will destroy the film. Check the

mica between the commutator bars. If it is

above the level of the bars, undercut it.

5-365

|