|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-233-14&P-1

5-78. APU INJECTION PUMP

This task covers:

a. Removal

c. Installation

b. Adjust

d. Follow-on Maintenance

TOOLS REQUIRED

EQUIPMENT CONDITION

Tool Kit, General Mechanics, Automotive

APU Removed (see para 4-207.)

(Appendix B, Section III, Item 1)

Gear Cover Removed (see 5-68.)

MATERIALS/PARTS REQUIRED

Lubricating Oil (Item 10, Appendix E)

Oil Ring Seal (Figure 21 1, Appendix E)

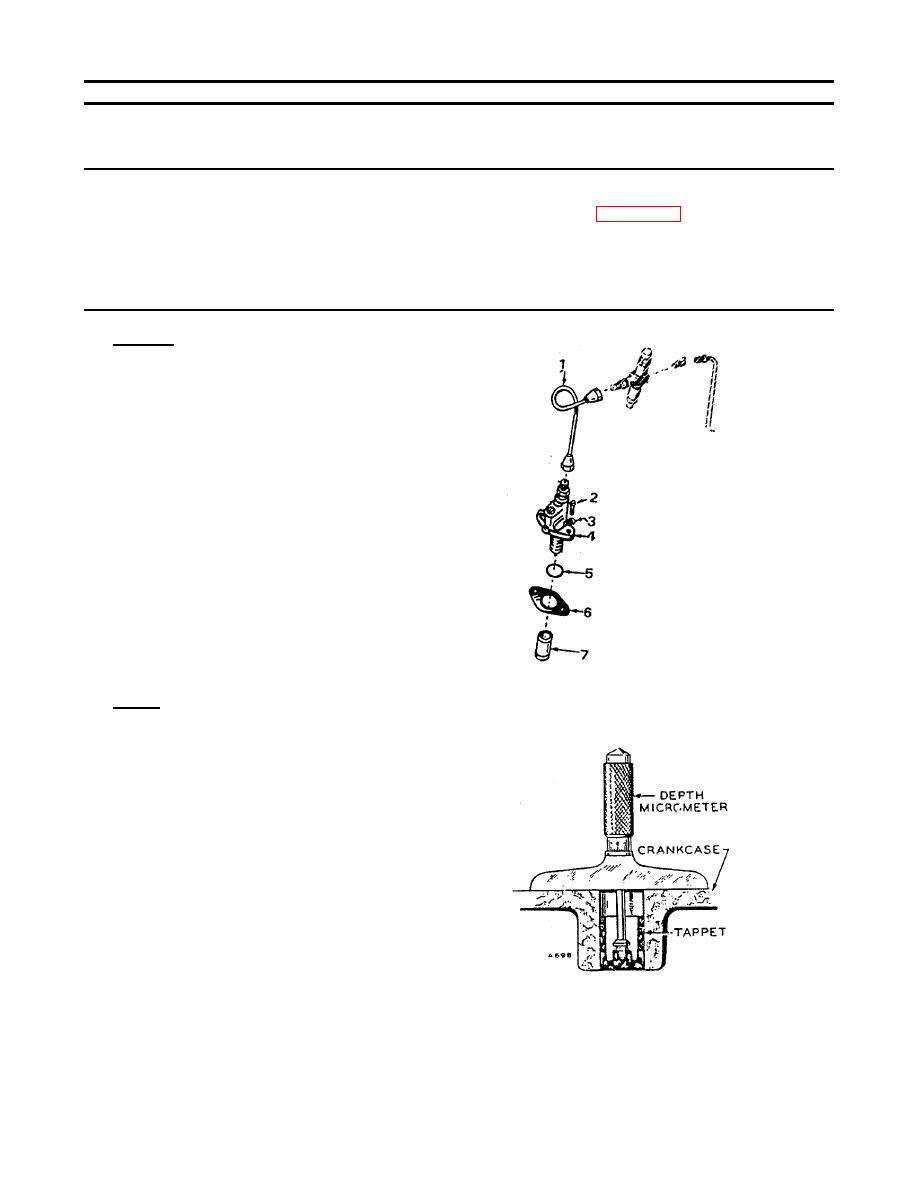

a. Removal.

(1)

Loosen screw and remove air housing panel.

(2)

Remove four capscrews, four flat washers,

plain housing panel, and nozzle housing panel.

(3)

Disconnect governor ball joint from injection

pump.

(4)

Tag and disconnect fuel hoses.

(5)

Tag and disconnect fuel line (1) from fuel

injection nozzle.

(6)

Cap all openings in pump, tines, and hoses.

(7)

Remove two capscrews (2), two lockwashers

(3), injection pump (4), O-ring seal (5), shim(s)

(6), and valve tappet (7).

b. Adjust.

(1)

Install pump tappet (7) in recess in crankcase

and position flywheel on the port closing mark

(PC) of the compression stroke.

(2)

Using a depth micrometer, measure the

distance from the pump mounting pad on the

crankcase to the center of tappet.

(3)

Determine required number of shims by

subtracting 1.670 in. (42.42 mm) from

dimension obtained in step 2.

(4)

Select shims to achieve required thickness.

5-402

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |