|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-233-14&P-1

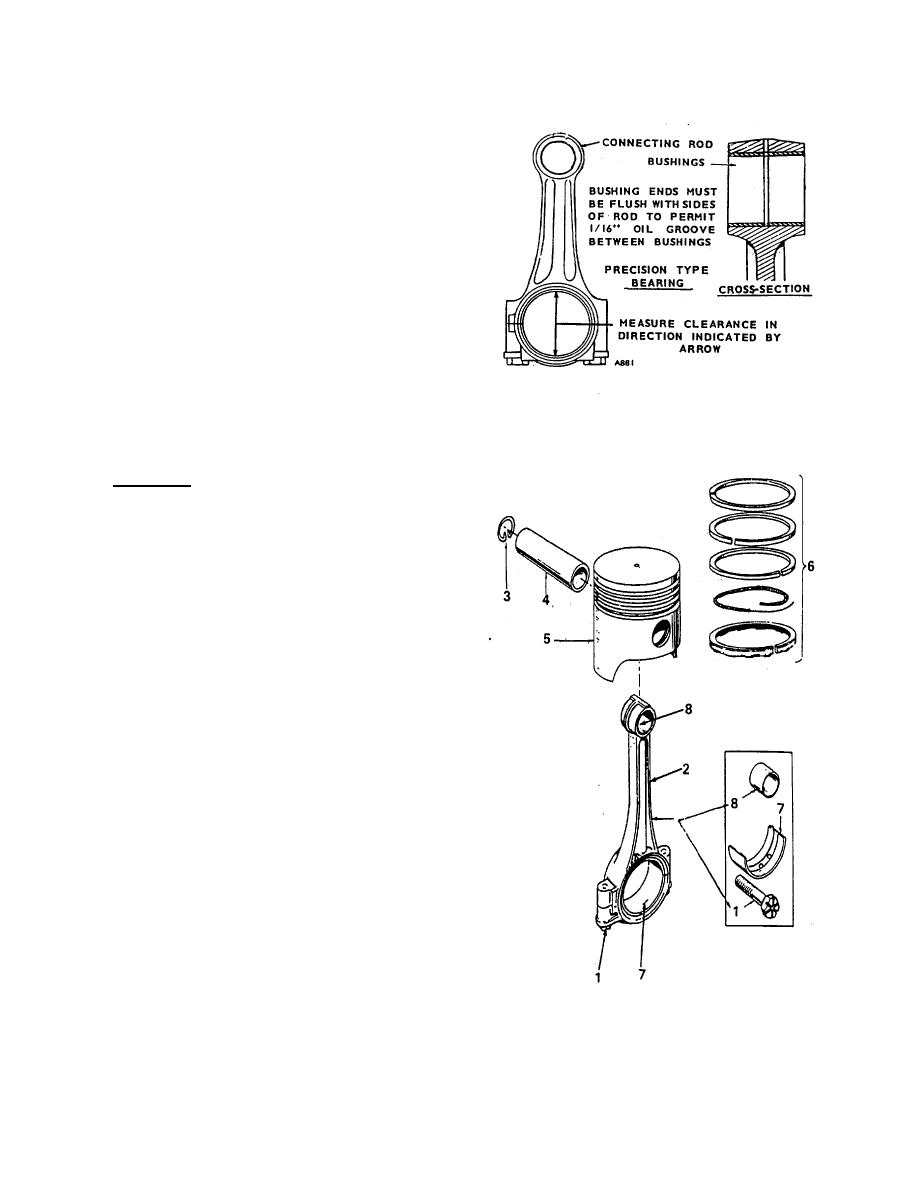

5-74. APU PISTONS, RINGS AND CONNECTING RODS - Continued

(7)

Clean the connecting rod and check for

defects. Check the connecting rod bushing

for proper clearance with the piston pin.

Clearance should be .0002 in. to .0007 in.

(.0051 to .0178 mm).

(8)

If the bushings are excessively worn, press

them out and press one new bushing in from

each side of the bushing bore. Press the new

bushings only until flush with the sides of the

rod to leave 1/16 in. to 7/64 in. (1.6 to 2.8

mm) oil groove in the center.

(9)

Inspect the connecting rod bearings for burrs,

breaks, pits and wear. Measure the clearance

between bearings and the crankshaft journal.

The clearance should be .001 in. to .0033 in.

(.0254 to .0838 mm). If necessary, place with

new standard or oversize precision bearings.

c.

Installation.

(1)

Install the connecting rod (2) in the piston (5)

with the pin (4) and retaining rings (3). If new

bushings (8) were installed, make certain the

ends are flush with the connecting rod to

provide for the oil recess in the center.

(2)

Using a ring expander, install the rings (6) on

the piston (5). Rings (6) will be marked top,

or identified in some other manner. Place

this mark toward the closed end of the piston

(5). Space the ring gaps one fourth of the way

around the piston from one another. No gap

should be in line with the piston pin. Oil (Item

10, Appendix E) the rings and piston. Gap in

oil ring expander must be approximately 1800

from gap in oil ring.

(3)

Position a bearing half (7) in the connecting

rod (2). Be sure there is not dirt under the

bearing. This could cause high spots and

early bearing failure.

(4)

Oil the cylinder wall. Install the piston and rod

assembly in the cylinder, using a suitable

installer. The assembly should be installed

with the stamp on the piston facing in the

same direction as when removed. The notch

on the piston should be towards the front of

the engine.

5-393

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |