|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-233-14&P-1

4-219. MITER BOX - Continued

d. Assembly.

CAUTION

Support inner races of ball bearings (13) when

pressing shafts (12) into them to prevent

damaging bearings.

(1) Press shafts (12) into ball bearings (13).

(2) Insert shafts (12) and bearings (13) into

housings (3) and press bevel gears (11)

onto shafts, aligning timing marks on shafts

and gears. Press gears on until spring pin

holes in shaft and gear are aligned.

(3) Rotate bevel gears (11) to align spring pin

holes with grease fitting and relief fitting holes.

(4) Insert spring pins (10) into miter gears (11) and use pin pun h to drive pins in until flush with gear

c

hubs.

(5) Use a spanner wrench to install two bearing retaining nuts (7), tighten till snug.

CAUTION

If same shaft (1 2) and bevel gear (11) assemblies are

reused, use same shims (4) as were removed to maintain

correct backlash of bevel gears.

(6) Press in two new oil seals (6) until they seat against bearing retaining nuts (7).

(7) Use a drift pin and hammer to drive locking pins (5) into housings (3) to secure bearing retaining

nuts (7) and seals (6).

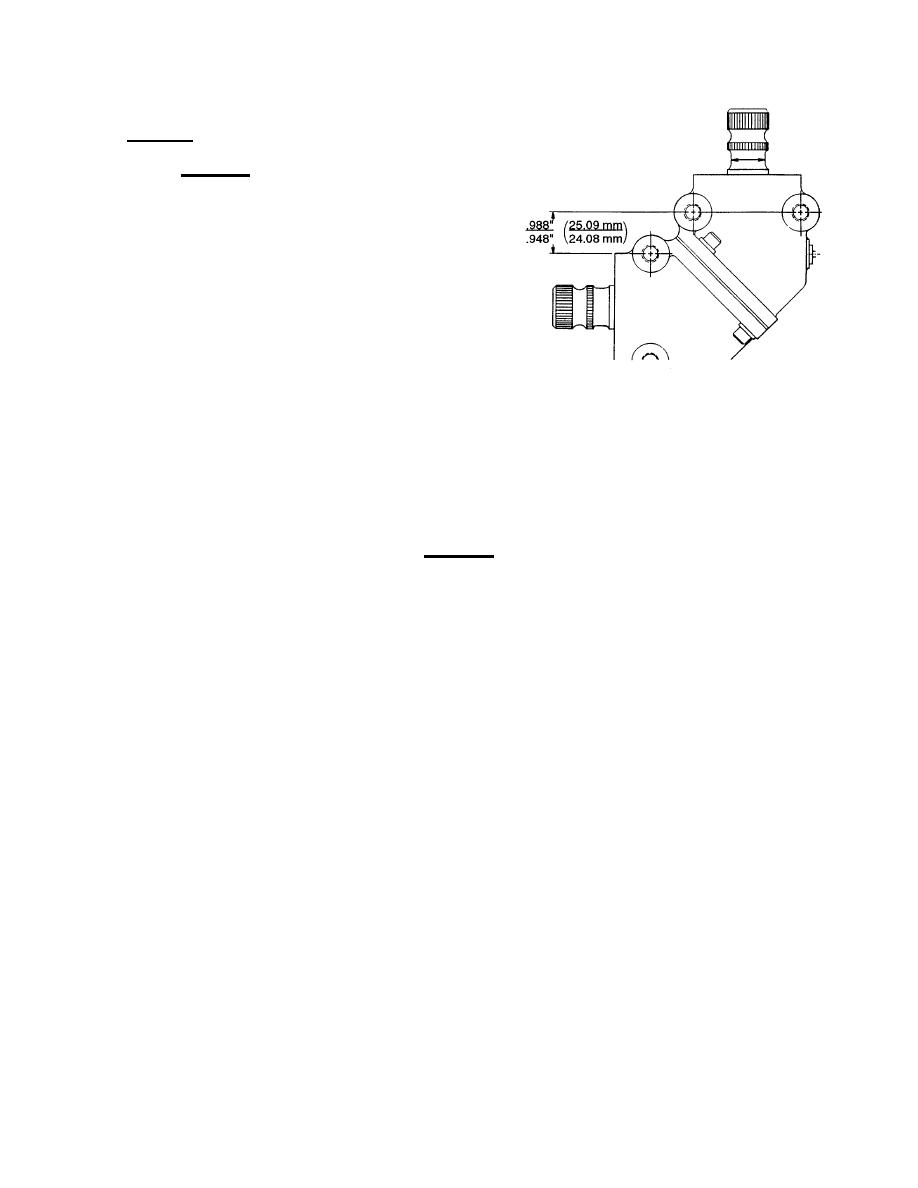

(8) Install shims (4) between two 900 miter housings (3). Thickness of shim pack must be adjusted to

maintain .948" to .988" (25.09 to 24.08 mm) between housings (see illustration).

(9) Install four screws (1) and lock washers (2) to assemble 900 miter boxes (3) together. Torque

screws to 35 ft Ibs (47.5 N.m).

(10) With one shaft restrained, total backlash measured at the other shaft to be less than or equal to

0.010 inches (.254 mm) when measured with a dial indicator at a point 2.00 inches (50.8 mm)

from center of the shaft. This equates to 0.10 inches (2.54 mm) movement on a 20 inch (508

mm) steering wheel.

(11) Install relief fitting (8) and grease fitting (9) in housings (3).

4-539

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |